The guide line for selection of plastic mould steel

The guide line for selection of plastic mould steel

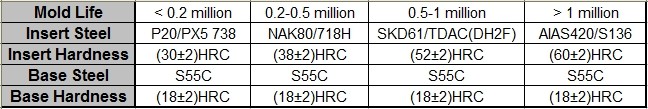

The plastic mould steel choice depends on expected mold overall life, part surface roughness and plastic materials .

The higher the overall life of the mold should be , the higher demand for wear resistance and hardness of plastic mould steel should ask for .

Transparent products require cavity to be mirror polished, and S136H, PAK80, PAK90 , 420 and other high-quality steel are better choice.

In terms of the plastic material, heat-sensitive plastics (eg PVC, etc.) must select anti-corrosion steel, such as S136H,PAK90 .

Relative sliding mold parts should use different steel and hardness, hardness difference is 2 HRC.

Steel for mold parts

Steel for mold parts

if mold core material and insert materials are same, the hardness of core should be below the insert hardness by about 4 degrees.

dowel pins material: SKD61 (52HRC).

steel for slide parts and core-pulling mechanism:

1.lateral slide parts and core or cavity inserts should be made of different steel if relative sliding is needed for them; But if it really need the same steel for mold inserts material and the sliding block,sliding block’ surface must be nitrided, and its hardness should be below around 2.

2. slider block material: P20 or 718.

3. locking blocks: S55C (required heat treatment to 40HRC) or DF2 hardened to 52HRC.

4.wear plate: DF2 hardened to 52HRC.

5.angular pins: SKD61 (52HRC).

6.wedge block: S55C.

7.guide block : DF2 (oil heat treatment of steel required to 52HRC).

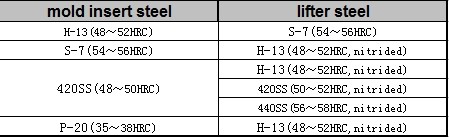

lifter steel: lifter steel and mold inserts steel can not the same for the lifter rod could be scratched when sliding.

Note: The lifter can also use beryllium copper (Be-Cu).

Note: The lifter can also use beryllium copper (Be-Cu).

Before Lifter nitriding,the appropriate clearance should be left for the lifter rod and lifter hole

Other parts steel:

a. standard gate steel is choosen by the manufacturer.

b. three plate mold sprue bushing : S55C (required heat treatment to 40HRC).

c. puller, stopper, support pillars: S55C.

d. other parts without special requirements, use the plastic mould steel S55C.