Plastic Cutlery Mould Maker

China Plastic Cutlery Mould Maker

China Cutlery Mould Company

We invite you to join the forefront of manufacturing furniture by joining the experts at China Cutlery Mould Company! We are passionate about what we do and have spent many years perfecting our knowledge regarding cutlery mould manufacturing and design. We don’t only make molds, but rather craft solutions that will meet your requirements.

High Production Capacity

In the current world of speed, it is evident how important time is. Our production capability is of the highest standard! Utilizing our top-of-the-line equipment and effective processes, we produce top-quality moulds for cutlery swiftly. It is our promise to give you exactly what you want, exactly when you want it.

Key Features:

- Efficient Processes: Our streamlined methods ensure quick turnaround times without compromising quality.

- Advanced Equipment: We invest in the latest technology to enhance production efficiency.

- Quality Assurance: Rigorous testing processes guarantee the durability and reliability of our moulds.

Quick Delivery

At China Cutlery Mould Company, we respect your time. The promise of speedy shipping means that you can count on us to fulfill tight deadlines. Because of our extremely efficient logistics plan, your package is delivered on time, regardless of how far the order has to be transported.

Delivery Advantages:

- Timely Shipping: We prioritize prompt delivery to meet your production schedules.

- Reliable Logistics: Our logistics team ensures that every shipment is tracked and managed effectively.

- Global Reach: No matter where you are, we can deliver your orders efficiently.

Strong Mould Durability

For furniture, quality is paramount. The moulds we make are designed to last, using top-quality materials and the most advanced methods. You’ll receive cutlery moulds that can withstand the demands of production while delivering flawless outcomes each time.

Durability Features:

- Robust Materials: We select only high-grade materials to ensure longevity.

- Innovative Design: Our moulds are engineered to perform under pressure and high volumes.

- Consistent Performance: Expect reliable results with every production run.

Unmatched Technical Support

We don’t stop at simply selling cutlery moulds. We’re here for you every step of the way with top-of-the-line technical support. Our team of experts is available to assist with any inquiries or problems you may face to ensure that your production runs smoothly.

Support Services:

- Expert Guidance: Our knowledgeable team is ready to provide assistance whenever needed.

- Problem Resolution: We address any issues promptly to minimize downtime.

- Ongoing Support: Our commitment to you continues long after the sale.

So, why should you pick China Cutlery Mould Company for your cutlery requirements? We offer quality performance, efficiency, and outstanding services to help you bring your ideas into reality. Contact us now to find out more about our offerings and discover how we can help your company! “`

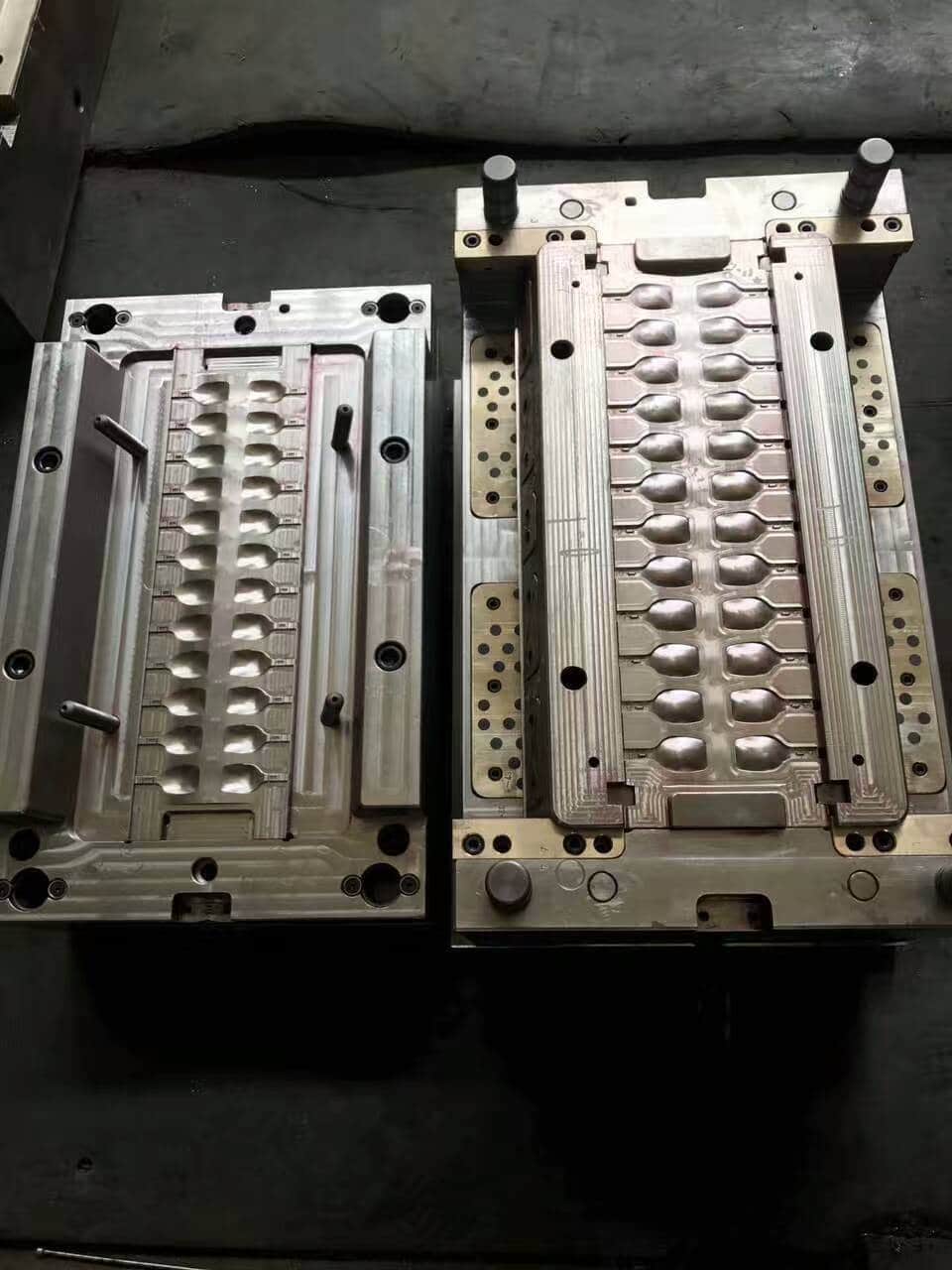

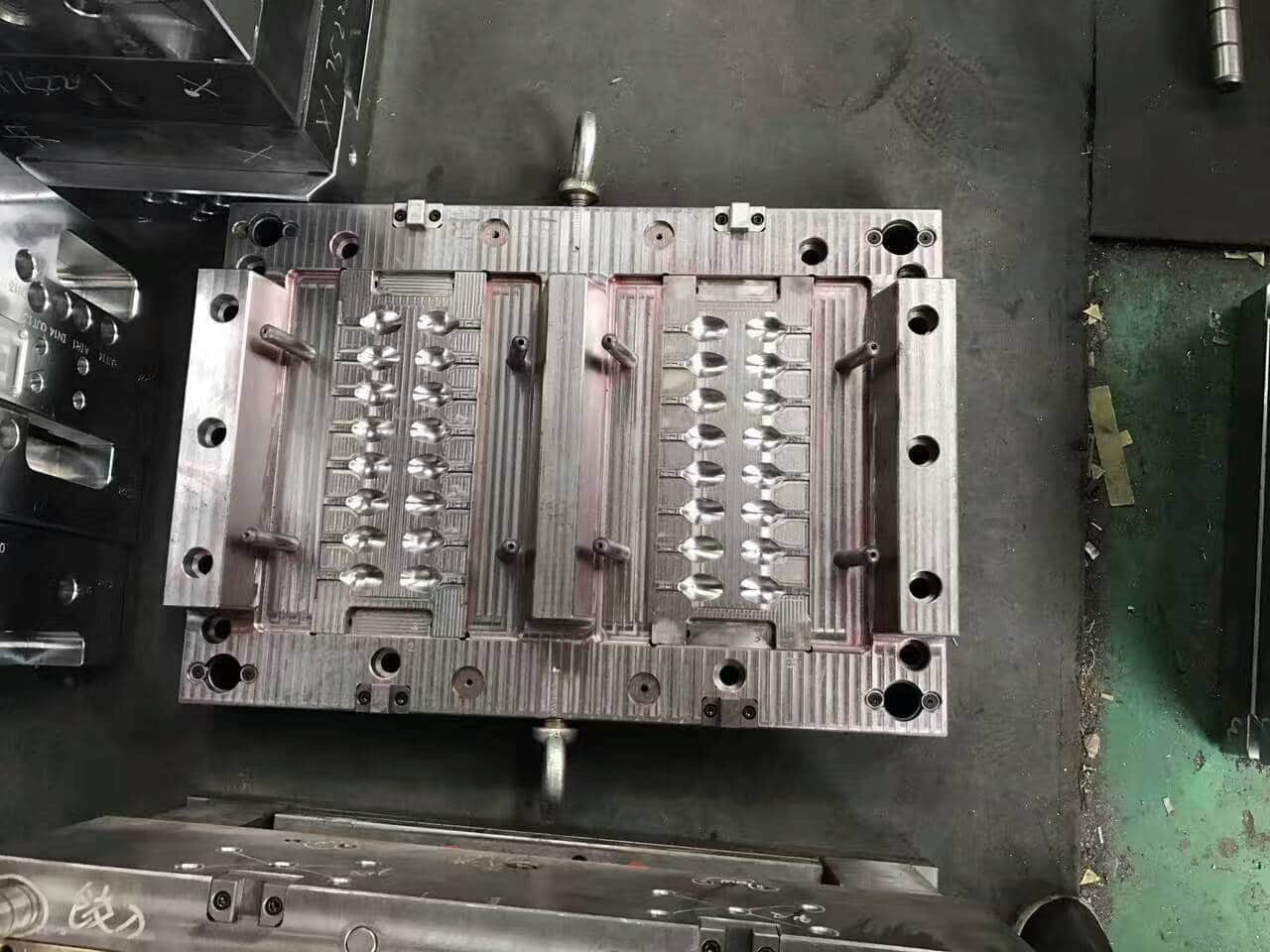

Plastic Cutlery Mould Gate positioning and design

The location of the gate is of importance with respect to the way in which the polymer flows into the mould impression. Other factors have to be taken into consideration when choosing a gate location, which includes:

- aesthetic considerations of the moulding;

- degating requirements of the moulding;

- design complexity of the moulding;

- mould temperature requirement;

- nature of the polymer to be processed;

- volume of the polymer to be fed through the gate and the feed rate;

- significance and positions of weld lines produced;

- possible locations and effects of gas entrapment created as a result of the filling profile.

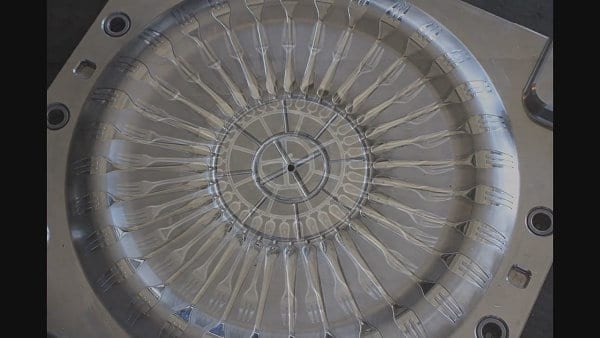

After consideration of all the previous points, it must be apparent that the positioning of the gate must be determined relatively early on and before the design build-up has started. If the forks, spoon and knife component is to be conventionally fed, i.e. non-hot runner, the gate location options are further restricted due to the limitations of the two-plate mould design. Restrictions exist because of the necessity of having to gate on a single plane about the mould split line. When confronted with gating requirements outside the scope of the two-plate design, the mould designer has the choice of selecting either the three-plate or the runnerless mould design formats in order to achieve the desired gate position.

Plastic Cutlery Mould Gate types

The cutlery mould includes Plastic Spoon mould, Fork mould, Knife Mould. Once the most probable gate location has been decided, a gate of the correct design and geometry has to be chosen. Gate designs differ according to their intended application. The factors which affect the choice of gate location also affect the choice of gate design to be adopted. For single impression cutlery moulds or individually large components, a directly fed gating system can be employed. In such cases an extended machine nozzle feeds directly onto the mould impression, thus removing the need for a runner system. To achieve an even fill of the moulding without weld lines, directly fed gates are usually situated at the geometric centre of the component, e.g. dustbin bodies, cutlery, buckets, spoon, forks, knives, bowls, etc., when possible.