YOU IMAGE ,WE FINISH

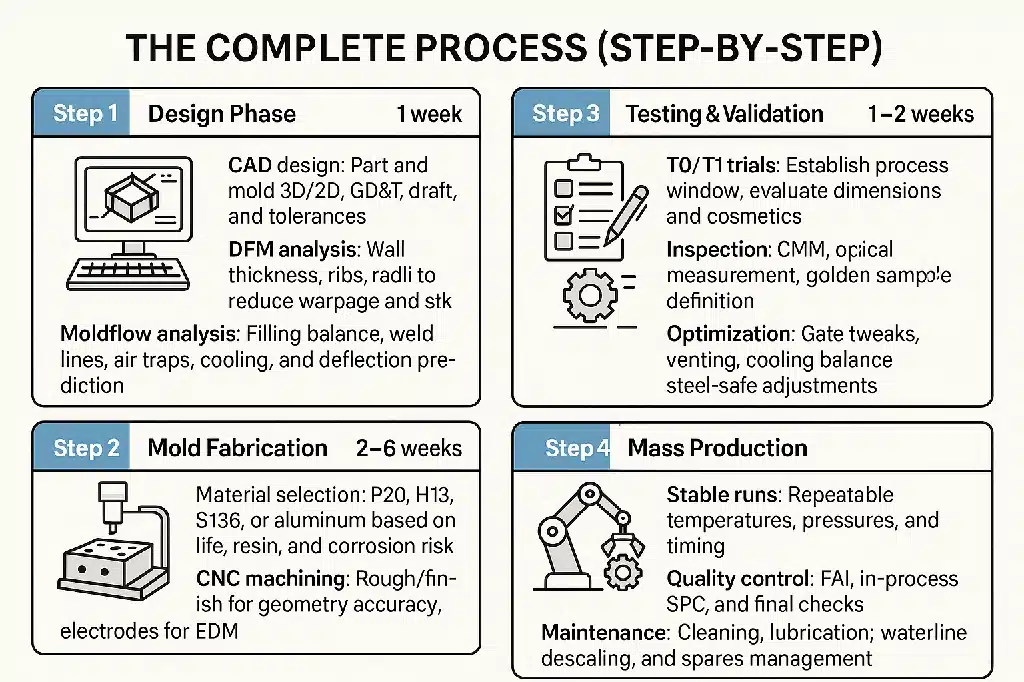

ONE STOP SERVICE FROM DESIGN,PROTOTYPE,

TOOLING,INJECTION MOLDING AND SHIPMENT

PRICE: 20% LOWER AND DELIVERY: 15 DAYS LESS

Established in 2005, PIM(Topworks) plastic mold company supplies design of plastics, contract plastic mold making, and custom injection molding service.

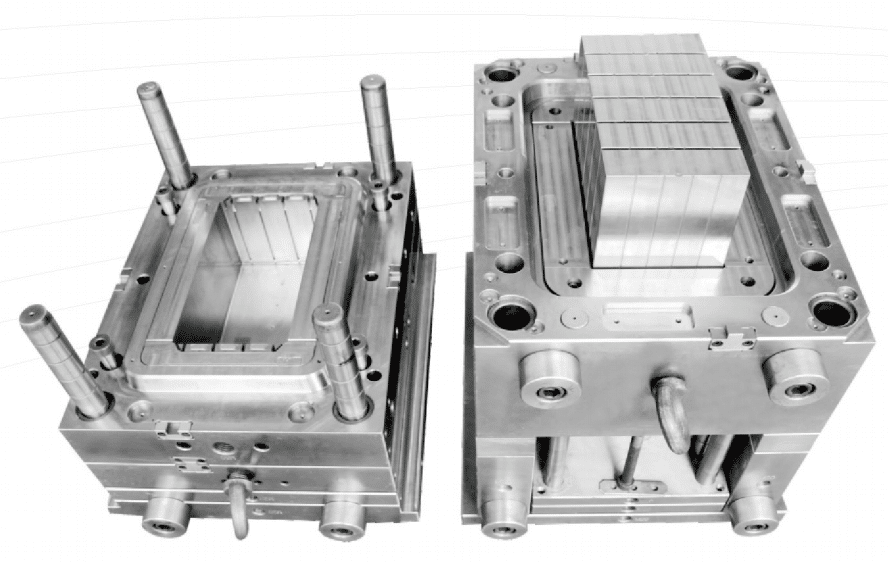

Endlessly, Topworks plastic mold manufacturer is dedicated to supplying top quality, tight tolerance contract plastic injection molds.

And now it becomes a key Chinese plastic mould company and contract tooling maker for high-quality plastic injection mold tooling.

Starting from humble beginnings in 2005 with 15 employees in a 500 square meter plant in Huangyan, known as a Chinese mold town with over 3 thousand plastics companies,

Today it has grown to employ 80 staff across locations in both Huangyan and Dongguan , including over 70 professional plastic mold engineers boasting rich mold-making experience.

Best Small to Medium-Sized Business (SMB) and Startup: Topworks is a good option to consider by businesses that need a high level of collaboration, personal service, and one-stop-shop, design to production. The fact that we concentrate on customer service and project management is a major benefit to clients that might not have the large in-house engineering staffs.

Talking to you straight means we can figure out what you need and get it just right. Our goal is to give you the best molds out there, custom-made quick and smart for what you ordered. We’re in it for the long haul – aiming to boost your workflow and keep you crushing it in the marketplace year after year. Teaming up with you means a lot to us and we can’t wait to keep this going strong as trusty partners down the road.

Some cases

injection mold with sliders

precise injection mould

injection mold

2k injection molding

ABS injection mold

ABS injection molding

What Our clients say

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

Cristiano

purchase manager

Steven is an excellent professional with great knowledge and technical practice.”

Paulo

CEO

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

David

CEO