As a Chinese manufacturer of custom injection molded products, we understand that clear communication is very important to providing the best services and products for our customers. To facilitate an accurate quotation, we need specific information to assess the requirements and produce the desired results. By providing essential details, you will not only receive a precise quote but also ensure a smoother production process.

This article aims to guide potential customers on what information they should provide to their Chinese injection molding supplier, so that they can receive an accurate and prompt quotation.

- Plastic Type

The first piece required is the type of plastic material for the custom injection molded product. Different materials have varying properties, costs, and processing requirements. Therefore, specifying the plastic type is crucial to the quotation process. Common plastic materials include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polystyrene (PS)

- Polycarbonate (PC)

- Acrylonitrile-butadiene-styrene (ABS)

If you are unsure of the best material for your product, your supplier can provide recommendations based on your product’s requirements, such as strength, flexibility, or resistance to chemicals.

- Flame Retardant Grade

The flame retardant grade refers to the material’s resistance to burning, which is important in certain applications like electronics or automotive components. Different grades of flame retardants are available, depending on the level of fire resistance required. Specifying the flame retardant grade will help your supplier choose the right material and additives to meet your requirements.

- Surface Requirements

Surface requirements cover various aspects of the finished product’s appearance and feel, including texture, glossiness, color, and any required coatings. Providing a detailed description of your desired surface finish is crucial for accurate quotations. Consider the following when detailing your surface requirements:

- Texture: Do you want a smooth, matte, or textured finish? Specify the desired surface roughness or texture pattern.

- Glossiness: Indicate the level of gloss you require, from high gloss to semi-gloss or matte.

- Color: Provide color samples, Pantone codes, or RAL numbers to communicate your desired color.

- Coatings: If your product needs a specific coating, like UV protection or antimicrobial agents, mention these in your request.

- Product Quantity

The quantity of products you require plays a significant role in determining the cost of production. Higher quantities often result in lower per-unit costs due to economies of scale. When requesting a quote, include the total number of units you need and any potential future orders. This helps suppliers assess their capacity to meet your demands and offer the most competitive pricing.

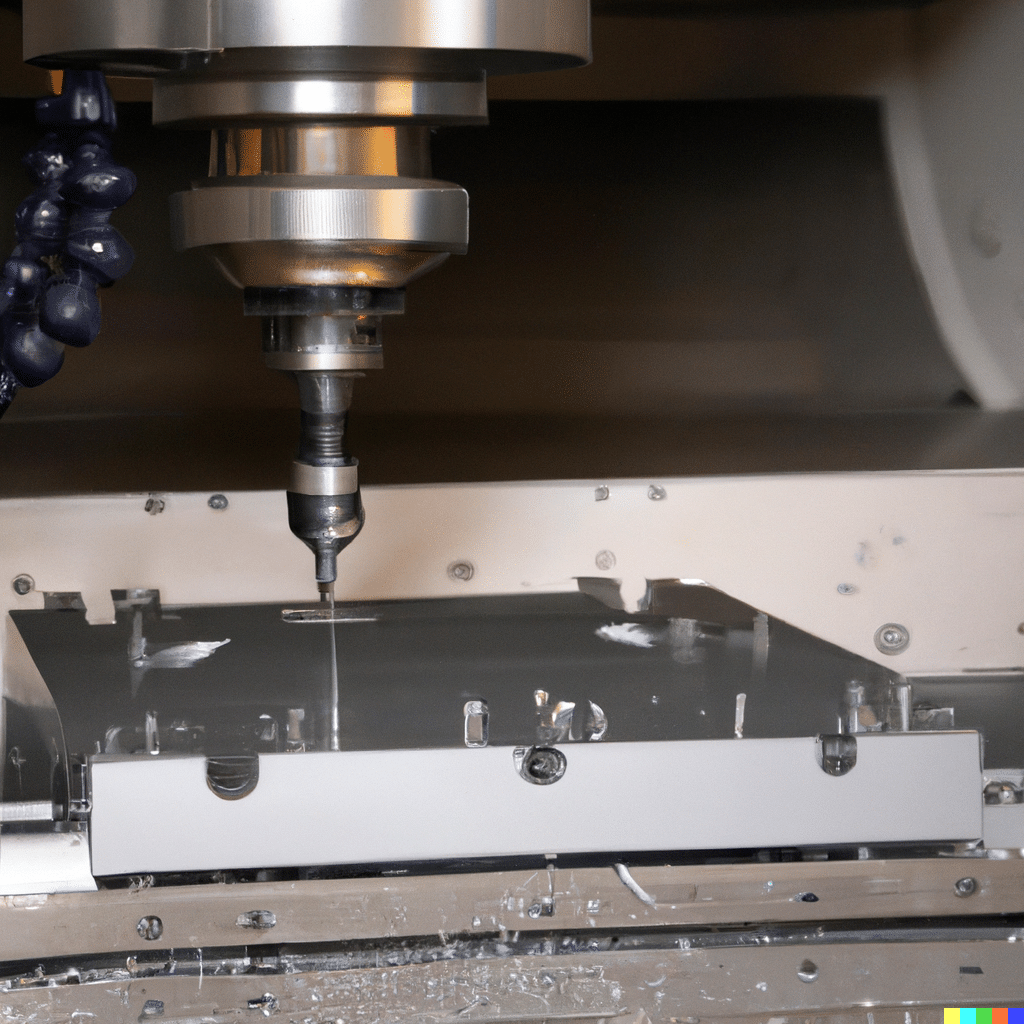

- Technical Drawings and 3D Models

Providing detailed technical drawings and 3D models of your product is essential for suppliers to understand the design, dimensions, and complexity of the project. These files should include all necessary information such as tolerances, assembly instructions, and critical dimensions. In addition to making the quotation process more accurate, having complete design files will help avoid misunderstandings and delays during the production stage.

- Special Requirements

If your product has any special requirements or certifications, such as RoHS compliance, FDA approval, or UL certification, please communicate this upfront. These standards may require specific materials, processing methods, or quality control measures that can impact the production cost.

Conclusion:

To receive an accurate and timely quotation from your Chinese injection molding supplier, provide as much information as possible about your project. This includes the plastic type, flame retardant grade, surface requirements, product quantity, technical drawings or 3D models, and any special requirements or certifications.