:、 初选注塑成型设备

(一)注塑成型设备的分类

1、按注塑机加工能力分类

injection molding equipment

the classification of injection molding machines

1.the injection molding machine processing ability

| style | clamping force(KN) | theoretical injection volume(cm3) |

| mini | < 160 | <16 |

| small | 160〜2000 | 16〜630 |

| medium | 2500〜4000 | 800〜3150 |

| large | 5000〜12500 | 4000〜10000 |

| super large | >16000 | >16000 |

2.the profile characteristics of machine

- Horizontal injection molding machine: mold clamping device and the injection device is a horizontal line arrangement.

Advantages:not high body, easy to operate and maintenance, high degree automation, stable installment.

Disadvantages: cover large area

At present, most of the injection molding machine adopts Horizontal form.

- Vertical injection molding machine: the arrangement of mold clamping device and injection components is vertical.

优点:占地面积小,模具装拆方便,嵌件安装 容易,塑料能较均匀地进行塑化。

缺点:顶出制品不易自动脱落,常需人工或其他方 法取出,不易实现全自动化操作和大型制品注射; 机身高,加料、维修不便。

这类注射机的注射量一般在60cm3以下。(小型)

优点:比卧式注射机占地面积小,

缺点:放入模具内的嵌件容易倾斜落下。

Advantages: cover small area, easy assembly and disassembly, easy installation, plasticization can be more uniform.

Disadvantages: the molded product is not easy to automatically remove from the injection machine and need human force, not easy to achieve full automation and hard for large products molding; high machine, difficult for feeding and maintenance. Shot of this type of injection machine is generally below the 60cm3. (small)

3.Classification by plasticization

| function | plunger style | screw style |

| plasticization | the limited plasticizing capacity | screw rotation to increase the plasticizing capacity |

| plasticizing uniform | only pushing drive melt, the laminar flow, impossible to get good uniform state | good stirring and mixing,fairly plasticizing uniform |

| Injection pressure | due to pressure loss on shunt core, injection pressure must be 2 ~ 3 times higher than that of screw type | small pressure loss, injection pressure just 30% ~ 50% of plunger style, produce larger molding products |

| Melt retention | much on the shunt cone and barrel wall | less |

| Color ring | couldn’t be used | quick color change |

| part quality | easy deformation,unstable quality | stable quality |

Structure of screw plastic injection molding machine

- injection system: Composition: hopper, barrel, heater, metering device, screw (the plunger for plunger type injection machine), drive device, nozzle and other components.Role: make the polymer pellet or powder get uniform plasticizing and to be molten state , and with enough pressure and speed to push the melt into the mold cavity.

- mold closing system:Composition: platens, pull rod, mold closing mechanism, ejection device and safety door, etc.. Role:To achieve the mold opening and closing;Provide sufficient clamping force to make the mold close tightly;To eject molded parts after mold opening.

- the hydraulic system:Provide pressure and speed loop for injection molding machine.

- the control system:control of the injection molding machine procedures and actions, as well as the control of the process variables and mediation, including time, position, pressure, speed and etc…

Injection molding machine main technical parameters

- injection device parameters

The specified amount of injection molding (maximum injection volume): injection molding machine can achieve maximum ejection volume to shot in air(polystyrene as the standard) - locking parameters:The clamping force, the daylight of the molding machine, the maximum and minimum thickness of the mold.

- injection pressure

How to select injection molding machine

- injection volume

the theoretical injection volume by injection machine each time

V=(π*D2*S)/4

V=The maximum theoretical injection volume (cm3)

D= screw diameter, cm;

S=Maximum injection molding travel ,cm

- Nominal injection volume: In the injection molding process, due to the change of temperature and pressure, the density of plastic will change, plus with the material leakage, the maximum injection capacity of the injection molding machine(Nominal injection capacity)

V=K*(π*D2*S)/4

V=The maximum theoretical injection volume (cm3)

D= screw diameter, cm;

S=Maximum injection molding travel ,cm

K=Injection coefficient(crystallized polymers:0.85;Non-crystallized polymers:0.93)

- The actual injection shot should be within 80% of the nominal injection volume

0.8M>MS

MS =plastic molding weight(including runner)

M=Nominal injection volume weight

Injection pressure

Injection pressure: the pressure exerted by the screw on the plastic injection machine.

Function: to overcome the flow resistance from the nozzle, flow channel and the cavity.

The injection pressure of the injection molding machine should be larger than the injection pressure required by plastic molded.and it is related to the plastic variety, shape and size of the plastic parts, injection molding machine type, nozzle , the resistance of the mold flow channel and so on.

In fact, the injection pressure of thermoplastic injection molding can be determined by theoretical analysis, and the flow simulation analysis with the software (moldflow) is more reasonable and accurate.

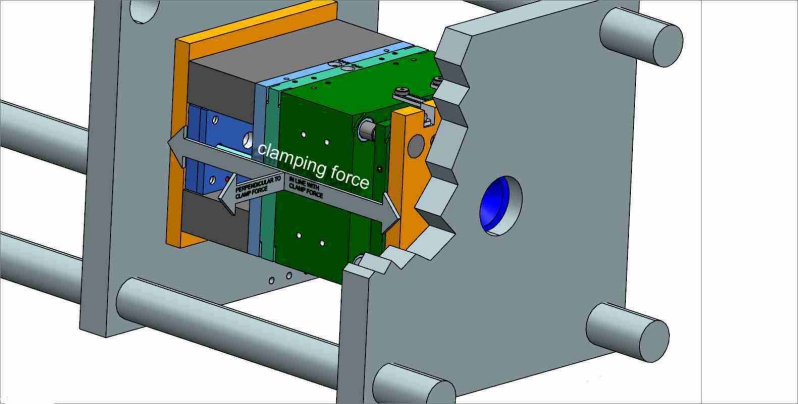

Clamping force

The clamping force is used to overcome the force tend to open the mould due to high pressure along the parting surface.

Pc=k*P

Pc=cavity pressure, MPa;

P=injection pressure, MPa;

k=Pressure loss coefficient(from 0.25 to 0.5)

T>Pc*k*A

T=injection molding machine clamping force, kN;

k=Safety coefficient, usually 1.1 ~ 1.2;

A=total projected area on the cavity of molded part and runner;

Pc=cavity pressure,normally 20-40 MPa

Insufficient clamping force–>PL opening–>material leakage

mold cavity number

Small batch production, just need the single cavity mold; As for the mass production, it is advisable to adopt multi cavity mold.As to large size plastic products, number of cavities will be decided by the limit of the max shot volume and the max projected area.

by the maximum injection volume of the injection molding machine

n=(k*Mc-Mf)/Mi

Mc= the maximum injection volume (weight) (g);

Mf=runner weight (g)

Mi=weight/unit (g)

k=Injection coefficient(crystallized polymers:0.85;Non-crystallized polymers:0.93)

Because of the different molding conditions and the nonuniform flow path of the melt to the

different cavity, it is difficult to get the same filling.As to the close tolerance parts molding,it isn’t a good idea to choose more cavities.

select the injection molding process parameters

add the polymer pellets and granules into the hopper of plastic injection molding machine,heated inside the barrel and get melted.Under the pressure,it enters into the cavities via nozzle,runner and gate.After cooled down and solidified in the cavities,the molded parts are removed from the plastic mould by ejection system.

injection molding

advantage:

- short Automatic molding cycle, high production efficiency, easy automatic production,

- plastic parts with the complex shape, precise size, and metal or non-metal inserts

- Stable product quality

- Wide application: So far, almost all thermoplastic plastics can be molded by injection molding. In addition, some thermosetting plastics can also be used with injection molding.

Disadvantages:

- The costly equipments like: injection machines and the other axulary equipments.

- complex structure injection mould

- high production cost, long production cycle, not suitable for small batch production

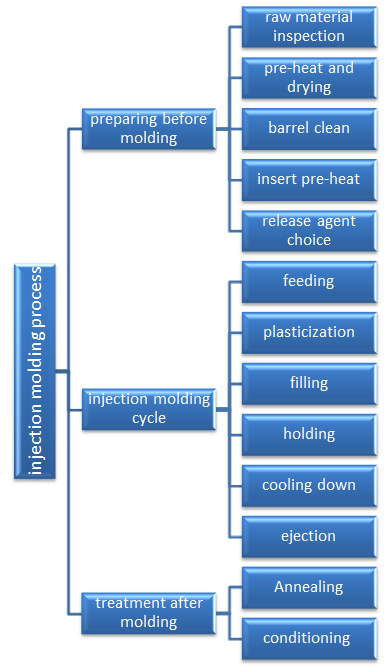

material inspection :the plastic color, pellets size and uniformity, fluidity (melt index, viscosity), thermal stability and shrinkage.

pre-heat and drying:Remove the excessive moisture and volatile material in the material to prevent the plastic parts surface defects or degradation, which would affect the appearance and the quality of plastic parts.

barrel cleaning:When changing the product, raw material and the color, the barrel need to be cleaned.

insert pre-heat:Reduce the temperature difference between the material and the insert, to reduce the shrinkage stress around the insert, and ensure the plastic parts quality.

release agent:The common mold release agents include zinc stearate, liquid paraffin, and silicone oil.

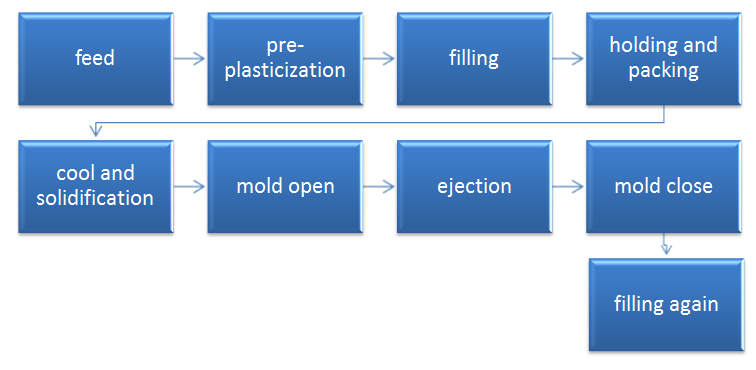

injection molding cycle

feeding:through the Hopper to add granular or powdery plastic to injection machine.

plasticization: By bands heating of the injection machine, the plastic material in the screw can be melted and become plasticized with good plasticity.

filling:The melted plastic driven by the injection molding machine plunger or screw, with a certain pressure and speed, goes through the nozzle and the mold running system and fill the mold cavity.

holding:after the cavity filled full, the injection machine plunger or screw still drive forward to maintain the pressure to fill material, so that the molted material in the barrel can continue to enter the mold cavity to compensate the shrinkage to prevent the melted plastic flow back

cooling after gate solidified:After a period of time, the molten plastic in the cavity is solidified, which ensures that the plastic part has enough rigidity when released from the mold to prevent the deformation and wrap.

ejection:after cooling enough,the molded parts would be ejected out of the plastic mold

internal force after molding

Causes of internal stress:Due to the uneven plasticization or the crystallization orientation in the cavity and uneven cooling; or because of the metal inserts or improper secondary operation.

The hazard of internal stress:Lead to deformation or crack during the loading.

Annealing treatment

The plastic part under constant heating in the liquid medium ,like hot water, hot oil or in hot air circulation oven for a period of time, and then slowly cooled to room temperature.

Temperature:10 degrees ~15 degrees higher than the usage temperature or of 10 degrees ~20 degree below the deformation temperature

Time:In general, about half an hour per the mm thickness.

function:eliminate the internal force,stabilize the size,improve the crystal structure, the elastic modulus and hardness.

Conditioning

A post processing method for accelerating the moisture absorption speed in the hot medium (boiling water and potassium acetate solution) quickly after released from the plastic mold. Plastic (mainly for moisture absorption material,such as PA)

Temperature: 100~121 degree

Time:The conditioning time is related to the thickness of the plastic part, which usually takes 2~9 hrs.

Purpose:Eliminate the residual stress; make the product reach the moisture absorption balance as soon as possible, stabilize the size .

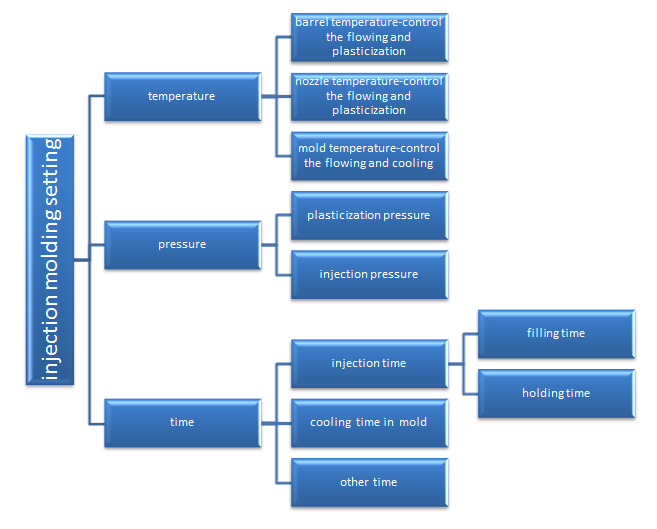

injection molding process setting

temperature:

barrel temperature:temperature should be between the viscous flow temperature (or melting point) and the decomposition temperature.

Plunger type barrel temperature should be 10 ~ 20 degrees higher than that of screw style.

The distribution of the barrel temperature generally follows the principle of high nozzle and low barrel end.Nozzle temperature:slightly lower than the barrel maximum temperature to prevent the nozzle drooling.But too low temperature on nozzle would lead to cold slugs to clog the nozzle, or the early solidified material would effect the quality.

Mold temperature:The temperature of the mold is determined by the plastic characteristics, the size and structure of the plastic part, the property and other technological conditions.

when the plastic mold temperature increases, the mobility increases.While density and crystallinity increases, shrinkage rate and productivity decreases

Mold temperature control:The mold temperature is usually controlled by the cooling medium,also it relies on molten material leading to the mold natural heating and natural cooling to achieve the balance.

Under special circumstances, the resistance heater can also be used to keep the temperature of the mold.

2 pressure

Plasticization pressure (back pressure): refers to the pressure applied on the top surface of the screw when the screw rotate back(screw type injection molding machine).Generally,under the circumstance of quality assured,the plasticization pressure should be as low as possible, maybe 6 Mpa about, but never more than 20MPa.

Injection pressure:refers to pressure overcoming melt flow resistance during mould filling , which ensure the filling speed of the melt .backing pressure could compact the melt and prevent the flowing back.this pressure is determined by the injection molding machine type, plastic varieties, mold structure, mold temperature,plastic wall thickness and injection system’ size and structure.