The Ultimate Guide to Understanding the Injection Molding Global Market in 2025

Introduction: The Rising Tide of Injection Molding

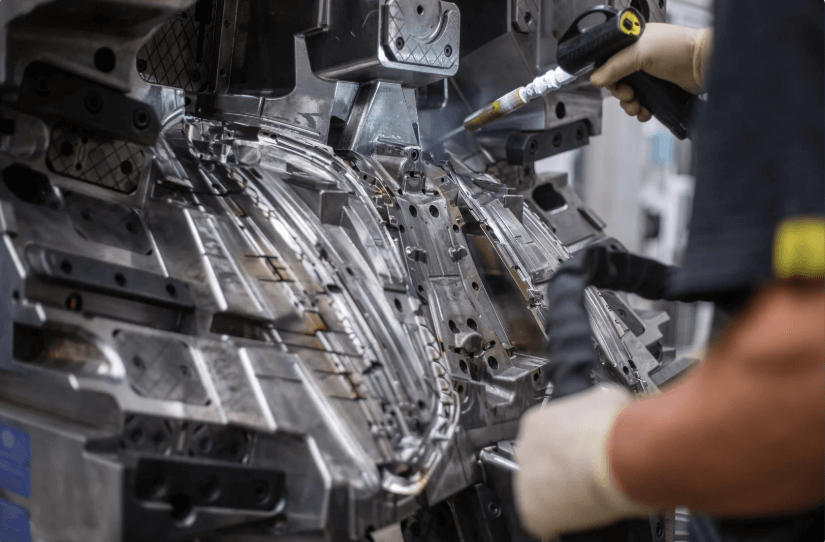

The injection molding industry is at a pivotal moment. As we look toward 2025, it’s clear that this sector is not just about producing plastic parts; it’s about innovation, sustainability, and meeting the evolving demands of a global marketplace. Are you ready to dive into the intricacies of this dynamic field? In this guide, we’ll explore the current landscape, emerging trends, and the future of injection molding, all while keeping our focus on how these changes will impact manufacturers, suppliers, and consumers alike.

The Current Landscape of Injection Molding

As of now, the global injection molding market is thriving, driven by advancements in technology and a growing demand for lightweight, durable materials across various industries. From automotive to consumer goods, the applications of injection molding are vast and varied. But what exactly is fueling this growth?

- Technological Advancements: Innovations in machinery and materials are making injection molding more efficient and cost-effective. For instance, the rise of electric injection molding machines has significantly reduced energy consumption and waste.

- Sustainability Initiatives: With the increasing emphasis on sustainability, manufacturers are exploring eco-friendly materials and processes. Biodegradable plastics and recycled materials are becoming more common, aligning with global efforts to reduce plastic waste.

- Customization and Flexibility: The demand for customized products is on the rise. Injection molding allows for high precision and flexibility, enabling manufacturers to meet specific customer needs without sacrificing efficiency.

Key Trends Shaping the Future

Looking ahead, several trends are set to shape the injection molding market in 2025 and beyond. Understanding these trends can help businesses adapt and thrive in an ever-changing landscape.

1. Smart Manufacturing and Automation

The integration of smart technology and automation into injection molding processes is revolutionizing the industry. With the advent of Industry 4.0, manufacturers are leveraging IoT devices and data analytics to optimize production, enhance quality control, and reduce downtime. This shift not only increases efficiency but also allows for real-time monitoring and predictive maintenance.

2. Growth of Medical and Healthcare Applications

The medical sector is witnessing a surge in demand for injection-molded products, driven by the need for medical devices, components, and packaging. As healthcare continues to evolve, so does the reliance on precision-engineered parts that can withstand stringent regulatory standards. Companies that can innovate in this space will find lucrative opportunities.

3. Expansion in Emerging Markets

Emerging markets, particularly in Asia-Pacific and Africa, are becoming hotbeds for injection molding growth. As economies develop and consumer spending increases, the demand for plastic products is set to soar. Companies looking to expand their reach should consider these regions as key targets for growth.

Challenges Facing the Industry

While the future looks promising, the injection molding industry is not without its challenges. Understanding these hurdles is crucial for manufacturers aiming to navigate the complexities of the market.

1. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains. Disruptions in the supply of raw materials and components can significantly impact production schedules and costs. Manufacturers must develop robust supply chain strategies to mitigate these risks.

2. Regulatory Compliance

As environmental regulations tighten, manufacturers face increasing pressure to comply with sustainability standards. Navigating these regulations can be complex, requiring investment in new technologies and processes.

3. Competition from Alternative Manufacturing Processes

Alternative manufacturing processes, such as 3D printing, are gaining traction. While injection molding remains a dominant method for mass production, companies must remain vigilant and adapt to the changing landscape to maintain their competitive edge.

The Role of Innovation in Injection Molding

To stay ahead in the injection molding market, innovation is key. Companies must continuously invest in research and development to explore new materials, techniques, and technologies. Here are a few areas where innovation is making a significant impact:

1. Advanced Materials

The development of advanced materials, such as high-performance thermoplastics and composites, is pushing the boundaries of what injection molding can achieve. These materials offer enhanced properties, including strength, durability, and resistance to heat and chemicals.

2. Enhanced Design Capabilities

Modern design software and simulation tools allow for greater creativity and precision in product development. Designers can create complex geometries and test them virtually, reducing time to market and minimizing costly errors.

3. Sustainable Practices

Sustainability is no longer just a trend; it’s a necessity. Companies are exploring ways to reduce their carbon footprint through energy-efficient processes, waste reduction, and the use of sustainable materials. Embracing these practices not only benefits the environment but also appeals to increasingly eco-conscious consumers.

The Economic Impact of Injection Molding

The economic implications of the injection molding industry are profound. As a major contributor to global manufacturing, this sector supports millions of jobs and drives economic growth. Here’s how:

1. Job Creation

The injection molding industry provides employment opportunities across various skill levels, from machine operators to engineers and designers. As the market expands, so does the need for skilled labor, fostering job growth in local communities.

2. Contribution to GDP

As a vital component of the manufacturing sector, injection molding contributes significantly to national and global GDP. The production of plastic goods supports a wide range of industries, from automotive to consumer electronics, creating a ripple effect throughout the economy.

3. Innovation and Competitiveness

A robust injection molding industry fosters innovation and competitiveness. Companies that invest in new technologies and processes can improve efficiency, reduce costs, and deliver higher-quality products, ultimately strengthening their market position.

Conclusion: Preparing for the Future

As we look toward 2025, the injection molding industry stands at a crossroads. The combination of technological advancements, sustainability initiatives, and evolving consumer demands presents both challenges and opportunities. To thrive in this dynamic landscape, manufacturers must embrace innovation, adapt to changing market conditions, and prioritize sustainability.

In conclusion, understanding the injection molding global market is crucial for anyone involved in manufacturing. By staying informed about trends, challenges, and opportunities, businesses can position themselves for success in the years to come. So, are you ready to take on the future of injection molding? The journey begins now.