Injection Molds from China: The Comprehensive Guide to Buying Injection Molds

If you are in manufacturing, you have likely thought about ordering injection molds from China. With prices typically 30-50% lower than Western manufacturers and are getting more and more advanced, Chinese mold makers have become a popular choice for companies around the world. But it can be a daunting process, especially if this is your first time.

After working with dozens of Chinese mold manufacturers over the years, I’ve learned that preparation, communication and knowing what to look for can lead to success. This comprehensive guide will guide you through every step of the process, from finding the right supplier to receiving your finished mold.

Why You Should Buy Source Injection Molds from China

Of course, before we discuss the how, we should discuss the why. China is now the leading manufacturing country in the world for good reason:

- Cost Savings: The greatest advantage is obviously cost savings. Due to mold complexity, you can save 40-60% compared to what you would pay for in North America or Europe. For a medium-complexity mold that would cost $50,000 in the US, for example, you could pay $20,000-30,000 in China.

- Manufacturing Capacity: China has made the investment in state-of-the-art machining equipment. Many Chinese mold workshops have the same CNC machines, EDM machines, and CMM inspection equipment as any Western shop.

- Speed: Speed can also be impressive. Once the relationship has been built, Chinese manufacturers tend to operate round the clock in order to meet deadlines. Work that would ordinarily take 12-16 weeks in other places can be accomplished in 8-10 weeks.

- Skill Mastery: Some skill mastery is of importance. Chinese manufacturers have great expertise in complex geometries, multi-cavity molds, and high-volume production tooling. They’ve honed their ability by working with brands around the world for decades.

However, there are challenges to sourcing from China. Quality can vary greatly between suppliers, communication is a challenge, and intellectual property protection must be watched carefully. This guide will provide you with a way to deal with these challenges successfully.

Step 1: Getting the Right Supplier

Your relationship with the supplier will either make or break your project. Here’s how you can find manufacturers worth your time.

Online Platforms

Use the major B2B platforms, just be smart about how you use them. Alibaba is the 800-pound gorilla, and there are thousands of mold manufacturers listed. Made-in-China and Global Sources are also good resources. When searching these platforms, do not just look at the first page of results. Go deeper, read reviews thoughtfully, and observe how long suppliers have been verified members.

Look for Gold Suppliers or verified manufacturers which have histories of transactions. Look at their responses and response time. A vendor who takes three days to respond to initial inquiries probably will be slow all the way through your project.

Trade Shows

Attending trade shows is a priceless way to get face-to-face time if you can afford it. The Canton Fair (held twice a year in Guangzhou) is large but overwhelming. Chinaplas is more concentrated on plastics and molds. These events provide an opportunity to evaluate professionalism, English proficiency, and technical knowledge face to face.

Direct Outreach

Once you have identified potential suppliers, check their websites. Professional manufacturers have elaborate English sites with case studies, equipment lists, and certifications. LinkedIn is a very effective place to search directly for factory managers and engineers.

Getting Referrals

Often the best suppliers are referred. Ask in industry forums, Facebook groups, or ask people in your network. A recommendation from a human who has actually worked with a supplier is more valuable than a hundred reviews on the Web.

Step 2: Getting Ready Your Requirements

Before reaching out to the suppliers, make sure you have organized your requirements. The more accurate you are with the beginning step, the more accurate your quotes will be.

Technical Information of the Essence

Deliver fully-featured 3D CAD data in standard formats such as STEP or IGES. You should include everything, not only the main part. If you have 2D drawings with critical dimensions and tolerances, add that, as well.

Have the material requirements clearly stated. Don’t just say “plastic.” Specify the exact grade: ABS 757, PP T30G, PC/ABS FR3002, etc. Material choice has an impact on mold design, cooling, and steel.

Be honest to define your production requirements. A mold for 10,000 parts is going to be different than one that needs to be created for 1 million parts. Define projected cycle life of the mold. State if you need family molds, multiple cavity molds, or hot runner systems.

Be specific about your quality expectations. What are the Critical Tolerances? What kind of surface finish are you looking for? Are there any special certifications required? Will the pieces be structural, visible, or both?

Additional Considerations

Think about future needs. Would you like to make design changes in the future? Do you require that the mold be exportable? Will you be using it at multiple facilities? Address these upfront.

Realistically take into account your timeline. Rushed jobs can be done, but at a high price and at potentially poor quality. Give yourself enough time for design, manufacturing, sampling, and shipping.

Step 3: Evaluating Quotations

Quotes for a new installation will come in a wide range of costs, from remarkably low to reasonable. How to properly evaluate them.

Learning Quote Components

A detailed quote should be provided, breaking down costs, including mold base, cavity and core machining, hot runner system (if applicable), texturing, sampling, and shipping. Unusually cheap quotes are usually hiding costs that will become apparent later.

Ask them about the steel that will be used.

- P20 is the most common for medium volume production.

- H13 is better suited to higher volume or abrasive materials.

- S136 is used for resistance to corrosion.

The steel grade has a significant impact on the life of the mold.

What definition or definitions of sampling should be used? How many trial shots? What modifications are done? Some suppliers offer only one trial run with their base price and charge for alterations.

Red Flags to Watch For

Be suspicious of quotes that are substantially lower than other quotes and have no explanation for it. Cheap prices usually indicate inexperienced manufacturers, low-quality materials, or hidden costs.

Aimless specifications mean the supplier doesn’t really understand your needs. Good manufacturers ask clarifying questions and may even make recommendations for your design.

Bad English communication isn’t necessarily a deal-breaker, but it needs to be controllable. You’ll spend a lot of time talking about technical things throughout the project. If you are having trouble communicating now, then imagine yourself troubleshooting problems later.

Step 4: Due Diligence and Verification of Suppliers

Before entering into a contract with a supplier, ensure they are capable and legitimate.

Factory Audits

If possible, go to the factory yourself or hire a third party inspection house to audit them. Consider cleanliness, equipment, and organization. A factory in chaos will produce chaotic products.

Compare the equipment they have versus subcontract. Some of these manufacturers are in fact brokers. Ask to see their CNC machines, EDM machines, wire cutting machines, polishing machines, and CMM inspection equipment.

Certifications and References

Request copies of ISO 9001 certification and industry-specific certification. While certificates can be spoofed, the lack of them is worrying.

Ask customers in your area or industry to refer you. In fact, these references should be contacted. Ask questions about quality, communication, problem-solving, etc. Ask if they’ll do business with the supplier again.

Sample Review

Ask them to send you pictures or samples of comparable molds that they have produced. Quality molds have clean parting lines, smooth surfaces, and accurate details. Look at the quality or finish and attention to detail.

Step 5: The Negotiating and Contracting Stage

Once you have chosen a supplier, it is time to negotiate terms and finalize the deal.

Payment Terms

Typical payment terms are 40% up front, 40% prior to sample, and 20% upon sample approval. If the relationship is new, you should look into Alibaba Trade Assurance or escrow companies for extra protection.

Letter of Credit (LC) – used to secure large orders, but there are bank charges involved. T/T (wire transfer) is most common, but is less flexible if anything goes wrong. Never pay 100% upfront.

Critical Contract Elements

Mold ownership must be made clear. Please note that you are the owner of the mold and you have the right to export it. Some contracts have mold removal restrictions making it difficult to escape that supplier.

Please add detailed specifications as attachments. Reference CAD-Files, Material specs, & Quality requirements. Stated differently, if there is a dispute, what’s not written down doesn’t exist.

For acceptance criteria, it should be clearly defined. How many samples have to be perfect before you get final payment? What is an acceptable proportion? Include tolerance ranges and inspection procedures.

Specify warranty terms. Most quality manufacturers will warranty molds for 300,000 to 1,000,000 cycles (depending on design and usage). Clarify what’s covered: normal wear, breakage, or design flaws.

Include modification terms. How will they be able to deal with design changes? What are the costs for revision after sampling? Make sure you do this in writing before things go wrong.

Intellectual Property Protection

IP Protection refers to a specific set of laws that give you the right to safeguard your creations or inventions for a set time.

Have designs signed by suppliers in non-disclosure agreements before they are shared. While enforcement in China can be difficult, it puts legal precedent in place and shows that you take IP seriously.

If your designs are of value, you may want to register them in China. Chinese IP law is getting better, but you can’t sit back and wait.

Watermarking your CAD files with your company name and part numbers won’t prevent theft but it does make it easier to identify stolen files.

Step 6: The Design and Engineering Process

After the contract is signed, the engineering phase starts. This is where communication plays an important role.

DFM Analysis

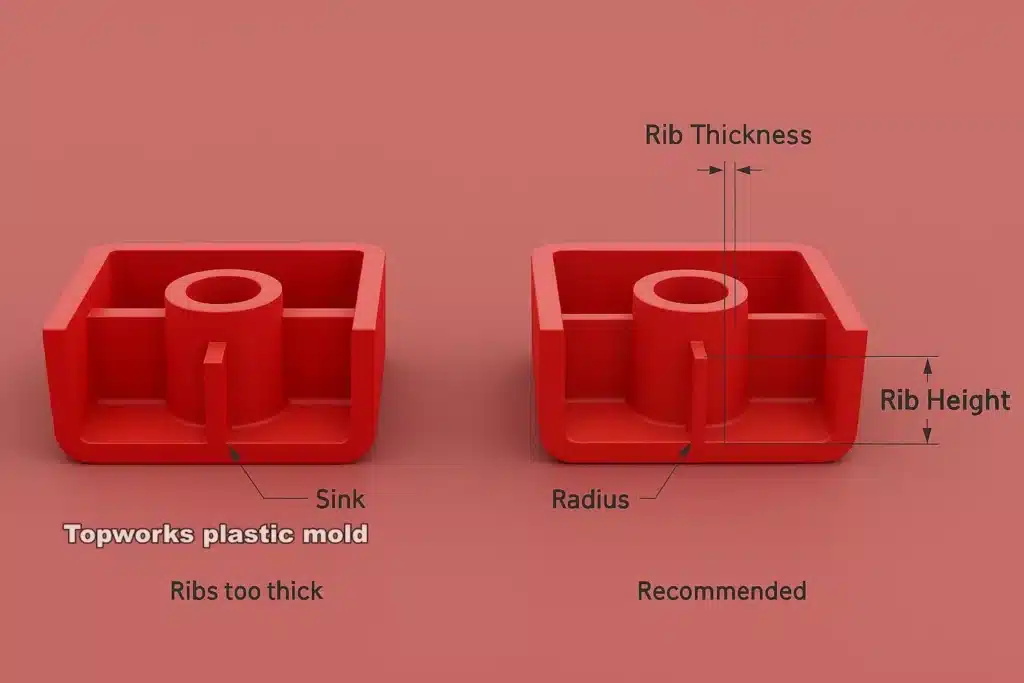

Good manufacturers can offer Design for Manufacturability analysis. They’ll look over your design and point out things like impossible draft angles, thin walls, sharp corners, or undercuts that make molding difficult.

Don’t get defensive about changes to the design. Experienced mold makers can provide feedback on ways to cut costs and make better parts. Give serious weight to what they say.

Mold Flow Analysis

If you have any complicated parts, ask for mold flow analysis. Software is used to simulate the flow of the plastic through the mold, which predicts weld lines, air traps, and warpage. This analysis saves costly issues in the future.

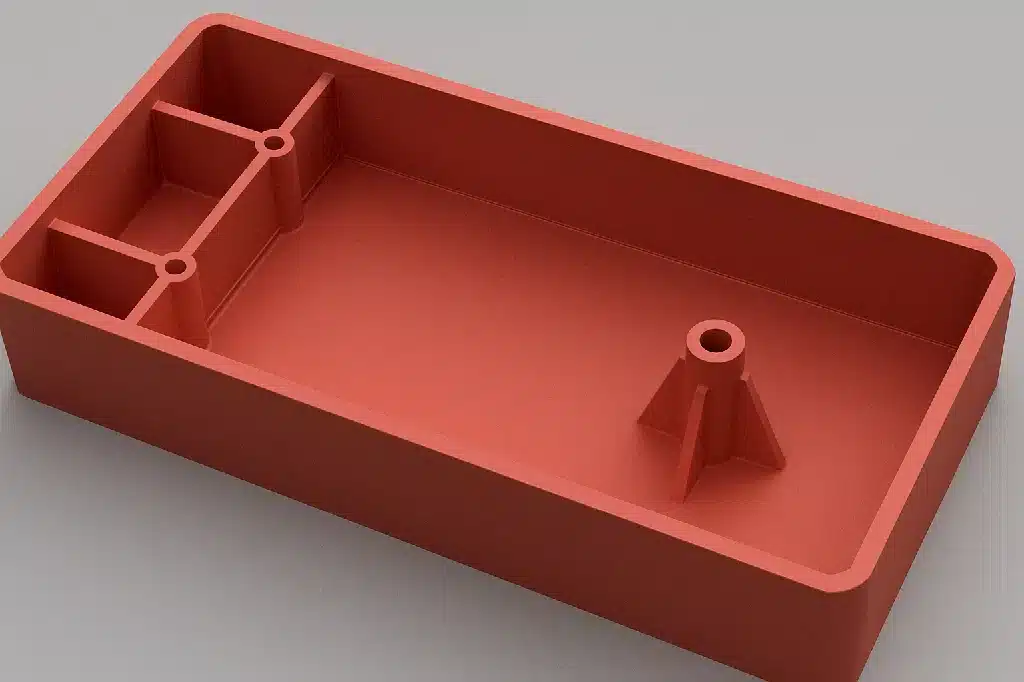

Gate Design, Runner System

Consider carefully the location of gateways. Gate position has an effect on appearance, strength, and cycle time. For the exposed areas, valve gates that leave a minimal impression are a good option.

In a multi-cavity mold, make sure of correct runner balance. Unbalanced runners result in uneven part quality between cavities.

Cooling Design

Adequate cooling is very important for cycle time and part quality. Ask About Cooling Channel Design. Conformal cooling channels (mold following part contours) are more efficient, but add to mold costs.

Step 7: Manufacturing & Progress Updates

During mold manufacturing, there should be constant communication.

Progress Tracking

Ask them to provide weekly photo reports of machining progress. Also, good suppliers easily provide pictures of rough machining, finishing, and polishing phases.

Inquiry about important events: when machining ends, when heat treatment is done, when assembly starts; This aids you in planning for sampling and production.

Problem Resolution

If design problems are found during manufacturing, correct them straight away. Delaying decisions slows down delivery and sometimes may lead to expensive changes in the future.

Be ready to be contacted in a timely fashion. Depending on where in the world others are located, you may need to respond outside of typical business hours on occasion.

Step 8: Sampling and Approval

Sampling is an opportunity to check that the mold is up to snuff before making a final payment.

First Article Inspection

Request a First Article Inspection report. It includes measurements, weights, and visual properties of early examples. Be very cautious when you compare your specifications to measurements.

Don’t accept “close enough.” If critical dimensions are out of spec, insist on corrections. It is much easier to fix now than after the mold ships.

Sample Testing

Functional testing of test samples is preferable. Do parts assemble correctly? Are they of a strength that is adequate? Check out appearance under proper lighting.

In multi-cavity molds, take multiple samples from each cavity. This means that cavity to cavity uniformity is key to production efficiency.

Modification Cycles

Most molds require some conditioning after initial sampling. A small amount of polishing or steel removal is to be expected. If extensive modifications are present, this indicates poor engineering and should be of some concern.

Take a record of all changes that have been asked for and agreed to. Make copies of emails showing what changes were done and why.

Step 9: Quality Control and Inspection

Before delivery, check for the quality of molds through inspection.

Third-Party Inspection

Consider using inspection companies such as SGS, TUV, or Bureau Veritas. They’ll check mold dimensions, surface finish, and functionality to your specifications.

The cost of inspecting is paltry compared to the cost of purchasing an unusable mold. Contractually include inspection rights.

Pre-Shipment Checks

Before shipping, ask for pictures of the finished mold. Look for clean surfaces, proper labeling, and protective measures.

Make sure all agreed-upon components are being included: spare parts, hot runner controllers, cooling manifolds, ejector pins, etc.

Step 10: Shipping and Receipt

Planning is essential to getting your mold safely to your facility.

Shipping Methods

Heavy molds are standard for shipping by sea. Shipping costs are moderate, but shipping takes 3-6 weeks (depending on location). Make sure you have proper crating, which will help keep them from damaging themselves.

Air freight is available in emergencies, but is 5-10x more expensive. Only use this for emergencies and small molds.

Documentation

Arrange for correct export documentation: commercial invoice, packing list, bill of lading, and certificate of origin. Improper paperwork leads to customs delays.

Documentation should clearly discuss ownership of the mold. This is important for customs and proves ownership.

Import Duties

Check with your country’s authorities about your mold’s import duties. Rates are different according to the type of mold and the country. Add these expenses to your budget.

If the mold is only used for a short period of time and then returned to China for use in production, then you might not want to get it under temporary import status.

Receiving and Inspection

The mold should be checked as soon as it arrives. Take photos before you accept delivery of the damaged product.

Test the mold promptly. Most warranties are time-limited from delivery rather than first use.

Common Missteps and How to Avoid Them

I’ve seen these mistakes again and again over the years. Learn from others’ errors.

- Choosing on Price Alone: The cheapest offer is not necessarily the best offer. A $15,000 mold making scrap is no bargain. A perfectly functional mold that will last for 500,000 cycles costs $25,000. Evaluate the total cost: morphology price + expected maintenance & modification and efficiency of production.

- Inadequate Specifications: Ambiguous requirements result in disappointment. Just telling someone to make it like the sample will not do. Documentation of all the needs in detail. If you don’t know how to specify something, ask the supplier how to do it. Good manufacturers make requirements as clear as possible.

- Poor Communication: Assumptions cause problems. If you don’t know about anything, ask. Make sure key information is in writing. Answer supplier inquiries in a timely way. Your delays are project delays.

- Skipping Sampling: Do not omit the sampling phase just because you don’t have enough time. Once the mold is shipped to your country, finding problems is exponentially costly compared to correcting them at the supplier.

- Ignoring Red Flags: If your gut says something is wrong, find out. It is painful to have to change suppliers halfway through a project, but it is worse to get back a mold that cannot be used. Trust but verify. Do not believe in promises without proofs.

Creating Relationships for the Long Term

It is important to have a great mold supplier. Nurture that relationship.

Repeat Business Benefits

Loyal customers are preferred by project scheduling, preferential pricing, and enhanced attention. Steady relationships are important to suppliers.

When a manufacturer knows your needs and expectations, he or she is able to assist in easier ways during future projects.

Clear Communication

After projects, provide feedback. What went well? What could improve? Professional vendors value constructive criticism.

Pay on time. Nothing ruins relationships like payment delays.

Growing Together

As your business expands, your mold supplier can expand with you. Established relationships offer flexibility in times of emergency.

You may want to visit your supplier at intervals. Face-to-face meetings strengthen partnerships and demonstrate commitment.

Final Thoughts

When it comes to injection molds, there are substantial benefits to purchasing injection molds from China when it is done properly. The keys to success are thorough preparation, careful supplier selection, good communication, and rigorous quality control.

Start with lower profile and less critical projects to try out suppliers before committing to major tooling. Take each project as an exercise in learning and development of process.

Keep in mind that the least expensive option is often not the most cost-effective. Take the time to find good suppliers and you will be rewarded with good molds that will work for you for years.

And the landscape is still in constant change. Chinese manufacturers are investing in automation, sophisticated materials, and engineering capabilities. Those who master how to work effectively with Chinese suppliers reap the benefits that have a long-term positive effect on their business.

Take the time to do it right. Your future self will thank you when you’re producing high-quality parts from reliable molds at competitive costs.

What is your experience when sourcing molds from China? Let us know your stories and tips in the comments below.