How Supply Chain Optimization Minimizes Risk in Foreign Consumer Electronics Manufacturing

Remember how that feeling of being sunk went through the roof when your entire product launch was held up by a single component supplier in Southeast Asia because of “unexpected issues”? Yeah, we’ve all been there. The global consumer electronics business moves at breakneck speed, and yet many manufacturers are simultaneously crossing their fingers in the hopes that their overseas supply chains don’t blow up.

So the thing is, supply chain optimization is not just about reducing costs anymore. It’s about survival. When you are producing consumer electronics overseas, you are essentially creating a house of cards that’s built on continents. One supplier hiccup, one geopolitical sneeze, one wrong move and your Q4 projections suddenly look like a toddler’s crayon drawing.

But what sets the companies who thrive from those who merely survive is that they have learned how to transform their supply chains from liability to competitive advantage. They’ve come to understand that real optimization requires designing systems that are so robust that disruptions are minor inconveniences and not existential threats.

The Cost of Supply Chain

Let’s do a quick statistical analysis for a minute. The typical consumer electronics manufacturer loses around 6-10% of annual revenue to supply chain inefficiencies. That’s not just late shipments–that’s everything from quality problems to inventory carrying costs to emergency air freight bills that make your CFO cry into their coffee.

Consider injection molding for example. By now you know how important those plastic components are to your devices, right? When your injection molding partner in China suddenly informs you they need three extra weeks because of “equipment maintenance,” you’re not just looking at delayed products. You’re looking at:

- Higher warehousing costs of finished components waiting for that single plastic component.

- Lost market share and cancelled customers.

- Higher shipping costs that can cost 20-30% of your margins.

- Lack of quality compromises due to rushing alternative suppliers.

The knock-on effects are punishing. One late injection molding run can ripple through your entire product line quicker than bad news spreads through a small town.

Foundation of the Supply Chain

Most manufacturers treat overseas supply chain optimization like whack-a-mole – responding to problems as they arise. Smart manufacturers? They’re playing chess. They’re playing five steps ahead and designing systems that can deal with whatever roundabouts the market chooses to throw at them.

Your supply chain ecosystem is not a list of suppliers. It’s a living breathing network of relationships, dependencies and vulnerabilities. Think about it like a spider web – beautiful and strong when built properly, and one broken strand can put the whole structure at risk.

The first step is simply to map everything. And I mean everything. Not only your tier-one suppliers, but their suppliers as well. You’d be amazed at how many electronics manufacturers find they are in fact reliant on the same raw material supplier through several avenues. Suddenly, the appearance of “diversified” supply base doesn’t seem so diversified anymore.

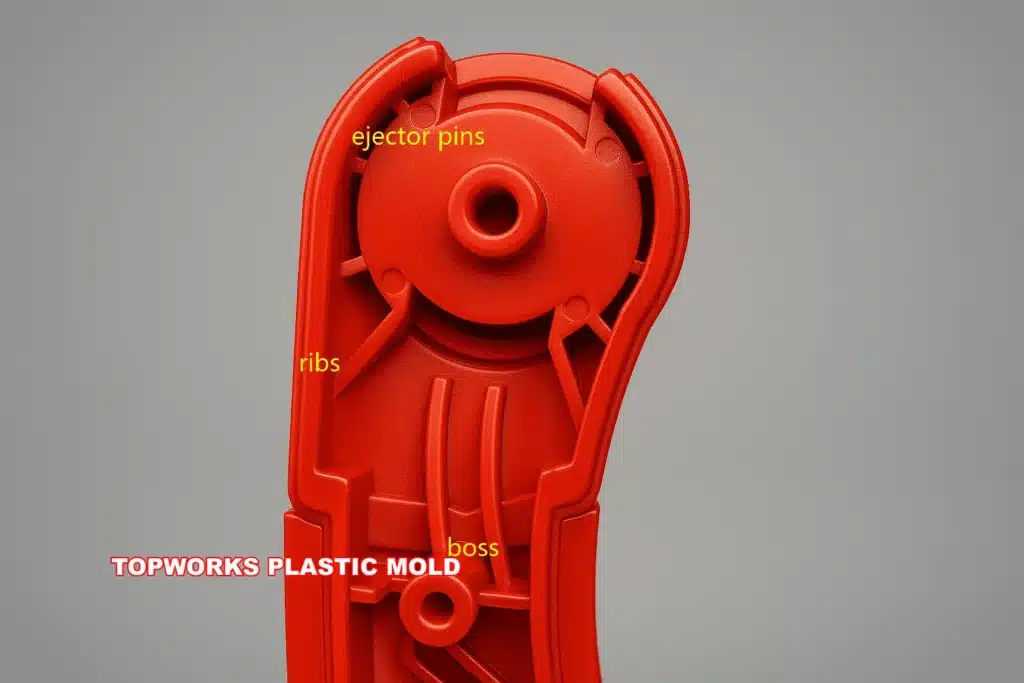

Begin with your critical components – those you can’t afford to lose tomorrow and shut down your production line. For most consumer electronics, this includes semiconductors, displays, batteries, and yes, those injection molded housings that everyone takes for granted until they’re not available.

Supplier Evaluation

Here is where most manufacturers go wrong. They assess suppliers like they’re buying commodities in a farmer’s market — cheapest price wins. But manufacturing abroad, particularly in the consumer electronics industry, is more like choosing a dance partner. Your partner needs to be able to dance to your beat, anticipate your movements, and not step on your toes when the music gets complicated.

Your supplier evaluation process should resemble an extensive background check more than a basic price comparison. Money is more important than you realize. That vendor that provides prices 15% below the competition? They may be cutting corners in ways you don’t know yet or worse, they may not be around next year.

Quality certifications are not just paperwork, they’re your insurance policy. Standards such as ISO 9001, ISO 14001, IPC standards for electronics manufacturing are not suggestions. They’re requirements. A supplier who is not properly certified is a pilot without a license – technically possible, not recommended.

But what really sets the good suppliers apart from the great ones is communication and transparency. When something goes wrong (and something always goes wrong), do they call you straight away or do you hear about what has happened when your shipment doesn’t arrive? The best overseas suppliers make your problems their problems because they know that your success is their success.

Risk Mitigation

Traditionally, risk mitigation in foreign manufacturing looks like purchasing insurance and crossing your fingers. Modern risk mitigation is more about making redundancy part of your DNA.

Geographic diversification is your first defense. Keeping all your suppliers in one region is like putting all your eggs in one very long distance basket. Political unrest, natural disasters or even localized labor strikes can bring entire manufacturing areas to a halt. Smart manufacturers have their supplier base spread across multiple countries and time zones.

There is an interesting fact though. The best manufacturers don’t simply diversify – they develop supplier networks that can actually talk to one another. When done correctly, your suppliers become your supply chain risk management partners. They share capacity and manufacturing capabilities during peak seasons, provide backup manufacturing capacity, and sometimes even share market intelligence that lets you make better decisions.

Inventory strategy is also hugely significant here. The old just-in-time model is great until it isn’t. Today’s consumer electronics manufacturers are finding a balance between lean inventory and strategic inventory. Safety stock for critical items with long lead times, but not working capital on items readily available elsewhere.

Injection molding tooling usually takes 4-8 weeks to get. Smart manufacturers maintain backup tooling at secondary tooling suppliers, even if it means additional upfront costs. When your lead supplier has problems, you’re not scrambling for alternatives-you’re implementing a contingency plan that you created.

Technology: Your Supply Chain’s Crystal Ball

Supply chain visibility technology has progressed from nice-to-have to absolutely essential. We’re no longer talking about simple tracking–we’re talking about predictive analytics that can identify potential disruptions before they occur.

Modern supply chain management software can track everything from supplier creditworthiness to weather that might impact shipping routes. They can plan ahead to predict when a supplier may have capacity constraints based on their other customer requirements. Some systems even monitor social media sentiment and news feeds to detect potential political or economic instability in supplier regions.

RFID and IoT sensors are also transforming the game for tracking components. Rather than wondering where your shipment is, you know exactly where every key component is located within the supply chain. Temperature-sensitive electronics components can be tracked during transit to make sure quality doesn’t suffer before they make their way to your manufacturing floor.

But technology is only as good as the hands it falls into. The best systems include automated monitoring with human expertise. Your supply chain managers shouldn’t be order processors, they should be analysts. They must know the market trends, geopolitical risks, supplier capabilities, etc. to be able to make strategic decisions, not just tactical ones.

Partnerships

Here’s something you may not know: the most successful consumer electronics manufacturers look at their overseas suppliers as strategic partners, not vendors. They invest in relationships just as they invest in R&D.

This means frequent site visits, collaborative planning meetings, and shared improvement efforts. When engaging with injection molding suppliers, for instance, involving them in your design process may minimize manufacturing costs while increasing quality at the same time. They know their equipment better than you–and you should use that knowledge.

Cultural awareness is more important than most western manufacturers understand. Business practices that are acceptable in North America or Europe may be totally unacceptable in your supplier’s country of origin. Spending time to learn local customs, business manners, and communication styles can help avoid misunderstandings that sink projects.

Payment terms and financial arrangements can also be effective partnership developers. Giving the good suppliers attractive payment terms generates loyalty that transcends contractual relationships. Suppliers will give preference to those customers who have proved they are committed to the relationship, therefore gaining capacity or access to material in times of scarcity.

Quality Control

Quality control for overseas consumer electronics manufacturing is completely different from domestic production. And you can’t just do final inspections–by then, it’s too late and too expensive to correct problems.

Quality checkpoints throughout the manufacturing process are a must. For injection molding processes, this translates to tooling inspection before production launches, tracking process parameters during production, and performing statistical sampling throughout each production run. Your quality requirements should be embedded into the manufacturing process, not tacked on afterwards.

Third-party inspection services can be invaluable for overseas manufacturing. Independent quality verification can be provided by third parties such as SGS, Intertek and Bureau Veritas at key production steps. This will provide confidence in your products without the need to have permanent staff at every supplier location.

Documentation and traceability is even more important when you’re manufacturing thousands of miles away. All components, steps in the process and quality checks should be recorded in remotely accessible systems. When quality problems occur (and they will) you need to be able to trace problems back to their source quickly.

Planning for the Unexpected

The most robust supply chains are designed with chaos in mind They believe that Murphy’s Law is not possible, it’s certain. Contingency plans to cover various failure scenarios are an integral part of your supply chain optimization strategy.

What if your main injection molding supplier has a significant piece of equipment outage? Do you have a backup tooling source at another supplier? What if there are political tensions between the country where your supplier is based and your home market? Do you have suppliers in other parts of the region that can increase production?

Financial Contingency Planning is important as well. Have access to credit for emergency situations. When you have to air freight components or pay premium prices to other suppliers, you don’t want cash flow issues to aggravate bad situations.

Production plans are not the only plans that matter. When things go wrong, your customers, stakeholders, and team members need to know what is happening and what you are doing about it. Publicly managing a crisis and communicating transparently can foster trust that pays off long after the short-term crisis is over.

The Economic Reality Check

Supply chain optimization is not an inexpensive task, and it’s important to be realistic about costs and benefits. Increased redundancy, safety stock, and multiple supplier relationships take investment to establish. But think of this: one supply chain interruption can cost more than years of optimization investments.

Think of it as your premiums for insurance. You’re paying a predictable amount of money for avoiding unpredictable catastrophic losses. The key is to strike the balance between the costs of optimization and risk mitigation benefits that are right for your particular business model and risk appetite.

Improvements in supply chain benefits should be calculated with both hard dollars and cost savings. Reduced inventory carrying costs and increased cash flow are tangible benefits. But how do you measure avoided stockouts, avoided customer dissatisfaction or retained market share during disruption?

Thinking Ahead

Fashion trends change faster than the consumer electronics industry and your supply chain strategy has to be just as flexible. New technologies such as 3D printing could limit reliance on traditional injection molding for some parts. Consumer electronics are being impacted by semiconductor shortages that result from the growth of the electric vehicle industry. Trade regulations can change overnight.

Successful manufacturers create flexibility in their supply chain strategies. They have relationships with innovative suppliers who can adapt to new technology. They track industry trends and scale back their supplier base accordingly. Most importantly, they see supply chain optimization as an iterative process, not a project.

Sustainability is quickly becoming a competitive necessity, not just a nice-to-have. Consumers and regulators are calling for transparency around environmental and social impacts across the supply chain. Your overseas suppliers must comply with these changing standards or they will become liabilities instead of assets.

What You Can Do Now

Supply chain optimization can feel like a daunting task when you consider all the moving parts, but successful implementation is reduced to taking small steps in a consistent manner. Begin with your most critical and greatest risks. You don’t have to fix everything at once — you need to start fixing the right things.

Start with a good supply chain mapping exercise. Start with your tier-one suppliers and then drill back to uncover dependencies you may not even be aware of Provide lead times, minimum order quantities and capacity constraints for each critical component.

Create supplier scorecards that are more than just cost and delivery performance. Include quality metrics, communication metrics, financial health metrics, and innovation capability metrics. Review these scorecards regularly and use them as the focus for improvement discussions with your suppliers.

Invest in technology which offers real-time visibility into your supply chain. Start with simple tracking and monitoring features and add predictive analytics as systems mature. Remember, the goal is not to have the most sophisticated technology, it’s to have the technology that allows you to gain actionable insights.

Most importantly, supply chain optimization needs to be treated as a strategic capability not merely an operational imperative. Those companies that do get it right in managing their overseas supply chains not only reduce risk, but also establish competitive differentiators that fuel growth and profitability for years to come.

The global consumer electronics market is not becoming any easier or any more predictable. Manufacturers who can successfully turn supply chain complexity into competitive advantage will succeed. Those who don’t? Well, they’ll keep crossing their fingers and hoping for the best. And hope isn’t a strategy for selling in today’s market.