The Way China Injection Molding Supports the Needs of Aerospace & Defense

The aerospace and defense sectors are reputed to be very demanding. Whether it is space exploration or even military activities, all components must be accurate, long lasting, and above all reliable. In the case of the production of these parts, there is no method in which state-of-the-art can be compromised. What then comes of injection molding in the mix?

China has proved to be an unquestionable market leader in injection molding, which is a manufacturing process that involves the process of injecting material into a mold to produce high-quality parts. Although injection molding can be viewed as a normal process, it is the detail and high-tech technology in the Chinese molding industry that makes the industry a good option in addressing the stringent demands of the aerospace and defense sectors. In this article, we will see how the injection molding capacities of China match these tough industries and why it is an ideal fit to manufacture aerospace and defense parts.

What is Special About Aerospace & Defense Manufacturing?

To begin with, we should first learn what makes aerospace and defense manufacturing so specialized. These may be an aircraft fuselage, a satellite component or a missile housing, but the parts many times involve high-performance materials that have to endure extreme environments such as fluctuating temperatures, extreme pressure and high speed operations. It is not merely durability but precision is key. A minor fault may destroy the performance of a whole system, endangering the mission or even lives.

The manufacturers involved in the aerospace and defense industries have to conform to stringent quality requirements. These are regulation compliance (to AS9100 (aerospace quality management) and MIL-STD (military specifications), and the ISO 9001 standards of general quality management. It implies that the material, process and even suppliers should be dependable, repeatable and have the ability to achieve precise tolerances with minimum error.

It is here that the injection molding industry in China comes in and takes center stage.

Why China? Why Injection Molding?

China has been referred to as the world manufacturing powerhouse over the past years. The leadership in manufacturing in the country cannot be associated with low cost-efficiency only; it is also about innovation, technological development, and highly skilled workers. As far as injection molding is concerned, China has done a great deal in supplying components that have stringent requirements as is the case with aerospace and defense industries.

Sophisticated Technology

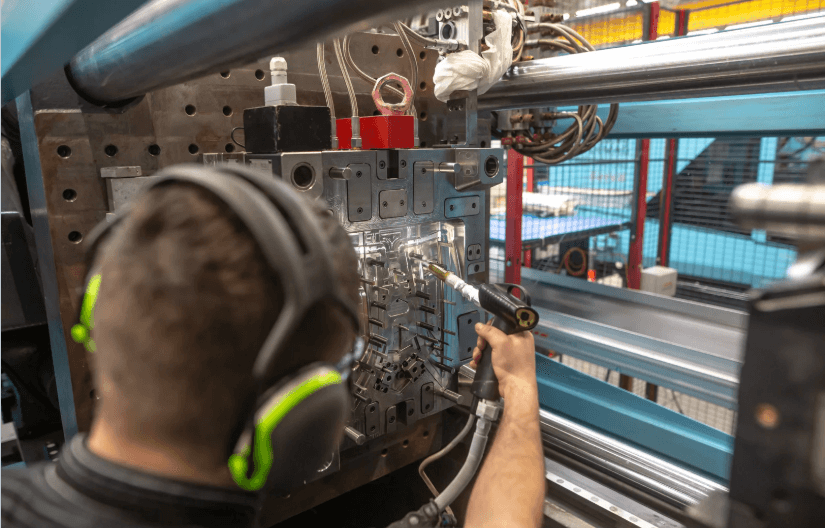

The injection molding industry in China has the most advanced technology, which assists businesses in ensuring that they have a firm grip on the manufacturing process. China manufacturers have access to the latest equipment like multi-cavity molds, high-speed injection molding machines, and robotic automation to produce very complex parts with high levels of precision. This is essential in aerospace and defense where tolerances are unbelievably tight and errors are disastrous.

Materials Expertise

Injection molding is more than the shaping of plastics. It is all about selecting the appropriate materials capable of withstanding the stresses that are involved in the aerospace and defense activities. China also has a wide selection of high-performance thermoplastics and thermosets, including PEEK (polyether ether ketone), polycarbonate, and Ultem, that have proven to be excellent in strength, heat resistance, and chemical stability. Such materials are ideal aerospace parts since they are resistant to high temperatures, harsh chemicals, and demanding mechanical forces.

Efficiency and Scalability

Scalability is one of the major benefits of injection molding. The mold has to be designed and fabricated, but when that is done, mass production is possible- which is why it is suitable in industries such as aerospace and defense where large quantities of parts are usually needed. The well developed injection molding factories in China can take large volumes of production and still maintain quality. They are able to revert complex and highly detailed parts at a remarkable speed making sure that projects are not delayed at the expense of performance.

Cost-Effectiveness

Cost rarely leads aerospace and defense manufacturing, but it is a pertinent factor. The developed infrastructure and developed supply chain in China enables manufacturers to manufacture high quality parts at a fraction of the cost of most of the Western competitors. This economics also means savings which can either be invested in more innovation or can be used to lower the total cost of the final product.

Injection Molding on the Go: Addressing Aerospace and Defense Requirements

So, now, we can have a closer look at the way injection molding, in particular, fits the requirements of aerospace and defense manufacturers.

Complex Geometries and Precision

Aerospace and defense parts are generally complex in design and precision. Injection molding can produce very intricate shapes which would be impossible or cost-prohibitive to make via alternative manufacturing processes. Products such as turbine blades, actuators, and sensor housings are frequently made with injection molding because it can make both fine detail and achieve uniform quality in high-volume production.

Durability and Strength

As we have indicated, components in the aerospace and defense industries have to work under harsh conditions reliably. The parts created under injection molding using high-performance materials are very wear and tear resistant, corrosive, and impact resistant. As an example, injection molding can be used in high-strength polymers and metals, which allows parts to withstand the hazards of jet engines or other missile components. The result? Very long life and endurance in critical operations.

Customization

The other benefit of injection molding is that it is possible to customize the components. The aerospace and defense systems commonly need components that are customized to a particular purpose and through injection molding, the size, shape and composition of the material used to make the part can be customized. As an example, parts that make up military drones, satellites, or aircraft cockpits must be made to strict specifications, and injection molding can enable these custom parts to be made with precision.

Rapid Prototyping and Repeat

In the industries where innovation and testing is important, the ability to quickly iterate designs and test new prototypes is a massive benefit. The injection molding process allows manufacturers to produce quick prototypes that are accurate and consistent which aerospace and defense engineers use to test new parts before deciding to mass produce. Moreover, the fast feedback cycle will guarantee that the engineers are able to optimize the designs without wasting time or resources.

Compliance and Quality Assurance

Certification is non negotiable in the defense and aerospace industries. Manufacturers are required to produce products of high quality assurance standards in order to satisfy international certification requirements. The injection molding companies in China are quite knowledgeable in satisfying these strict requirements. A large number of Chinese manufacturers have ISO 9001 certification, some even with more specific ones such as AS9100 aerospace or MIL-STD military grade. This guarantees that their components are of the best safety, reliability and performance.

Solving Problems in Aerospace & Defense Manufacturing

Although injection molding has immense advantages to the aerospace and defense industries, the process is associated with its share of problems that must be given due attention:

Complexity of Mold Design

Mold design of aerospace and defense parts may be a very specialized task. The complexity of the designs demand that the material qualities and the performance demands of the end product are well understood. Most of the leading injection molding firms in China have highly trained engineers who are specialized in aerospace and defense parts so that the molds are designed to suit the high demands of these industries.

Supply Chain Management

Aerospace and defense supply chains across the world are often complex, particularly when the manufacturers need to source materials and parts in other locations. China has strived to simplify its supply chain and guarantee good supply of components. Having access to high-level logistics and a developed system of suppliers, manufacturers will be able to make sure that parts arrive in time and are according to all specifications.

Intellectual Property Issues

Like any large-scale manufacturing process in the world, intellectual property (IP) protection is an issue. The major Chinese manufacturers utilize international standards of IP protection and make sure that their proprietary designs and technologies are stored in a safe place. Nevertheless, businesses are advised to conduct due diligence and do business with reputable suppliers to protect their innovations.

Conclusion: China Injection Molding – An Ideal Match with Aerospace and Defense

To sum up, the injection molding potential of China is a game changer in the aerospace and defense sectors. The synergy of high technologies, material knowledge, scalability, and affordability make China an ideal partner to the aerospace and defense producers. Be it in the quality production of the intricate parts with accuracy, durability and strength, or the provision of fast prototyping to test new designs, Chinese injection moulding provides the much required quality components that satisfy the stringent needs of these industries.

To the supply chain directors, and other decision-makers in the aerospace and defense industry, adopting the injection molding capabilities of China is a chance to enhance production efficiency, without compromising the quality and reliability that the industries require. Without doubt, the future of aerospace and defense manufacturing is being shaped in China.