Smart Automation in Small Batch Production: The Way It Changes Manufacturing Processes

When we imagine mass production, what frequently comes to our mind is the picture of huge and complicated assembly lines that churn out thousands of identical products, day after day. So what about small batch productions? That is a whole other animal, which is usually more nimble and customized to the needs of a particular customer. But small batch production also has its burdens, of course, including increased costs, narrower margins, and the eternal trade-off between quality and efficiency.

There comes smart automation. Small batch production has been revolutionized in the past few years, and all this is courtesy to smart automation. This technology is a game changer that does not just increase productivity but also aids in error reduction and envelope pushing innovation. Smart automation is an effective tool that all project managers, supply chain directors, or any individual in the field of industrial automation should be aware of as it is the future of manufacturing.

How this technology is changing manufacturing processes and why it is so important to a small batch producer trying to remain competitive in a more dynamic marketplace can be broken down.

The Small Batch Production Issue

Small batch production is considered as the underdog of production. In contrast to high-volume production, which benefits greatly due to economies of scale, small batch manufacturing is a delicate combination of precision, flexibility and speed. Every batch may be different in size, design, and material, which implies that production lines must be flexible and, at the same time, relatively efficient to ensure costs remain within limits.

This balance is hard to attain without automation. Manual work has the potential to cause uneven outcomes, a lengthy turnaround time, and a higher probability of human error. This is more so in the case of the industries that command high precision and customization like the automotive parts, medical devices and specialty electronics.

However, here is the thing; automation does not only apply to large-scale industrial production. Smart automation in small batch production can be of great use. Here is why.

Smart Automation in Small Batch Production is a Powerful Tool

What then is the secret behind smart automation? It is the employment of high-end technology, i.e. robotics, artificial intelligence (AI), the Internet of Things (IoT), and machine learning, not only to substitute human work but to augment it and streamline the entire system.

Smart automation assists small batch manufacturers to streamline the production in manners that would have remained unthinkable. This is how it can make a difference:

1. Increased Productivity

Smart automation has made production lines work faster, more efficiently, and less likely to slow down due to human fatigue or mistakes. Repetitive tasks can be programmed and performed by machines, fast and accurately. As an example, within small batch environment, it is possible to have robots rapidly adapt to new product designs and sizes without making a complete reconfiguration of the line.

To the small batch manufacturers, this implies that they can increase or reduce the production according to the demand. Smart automation flexibility is an important advantage, as it allows producing different quantities without compromising speed or quality.

2. Reduced Errors

Even the tiniest mistake in a batch may lead to severe consequences- this can be a bad product or even a late delivery. The likelihood of such errors is drastically minimized with smart automation. The real-time quality checks can be done by AI-driven machines identifying the defects before they are problems. Moreover, automation may assist in the strict quality control measures, as all the produced items are consistent and correspond to the required standards.

Automating the inspection process will allow manufacturers to release human employees so that they can perform the tasks that demand problem-solving and creativity, instead of time-consuming quality checks.

3. Greater Flexibility

The flexibility of smart automation is one of the most important benefits of smart automation in small batch production. Smart automation is flexible in nature as compared to traditional automated systems that were made to produce in large numbers. It can be programmed to accept minor changes in the product design, material selections or the production timelines, which makes it suitable in industries that need customization.

This flexibility does not only make the company more productive, it also enables small batch manufacturers to produce personalized or specialized products without incurring the cost and inefficiency of mass customization.

4. Cost Efficiency

One may think that it would be very expensive to invest in smart automation. Nevertheless, it may indeed assist small batch manufacturers to reduce their expenses greatly in the long run. To begin with, automation eliminates the use of manual labor which in some cases can be the largest manufacturing cost. Moreover, automation reduces the cost of production per unit, which increases the affordability of small batch runs, and allows the business to earn a higher margin.

Also, under predictive maintenance (found in many smart automation systems) the production lines are less likely to have a costly downtime because a machine fails unexpectedly. With the help of data and AI, such systems can tell when a part is likely to break down and warn the team beforehand so that the production process is not disrupted.

5. Creativity and Competitive Advantage

In the modern dynamic market, innovation is the main factor to remain ahead of the competition. Small batch manufacturers are able to test new product designs and production techniques with smart automation more readily. The automation system is so dynamic that new production processes can be adopted quite easily, which means that companies can now produce new products in the market within a very short time.

Automation offers the responsiveness and swiftness required by manufacturers that continuously improve their products and services-be it by offering different versions of an existing product, or by incorporating new technologies.

The Major Technologies Driving Smart Automation

So, before we go any further, here is a brief overview of some of the most important technologies that allow smart automation to achieve all of this:

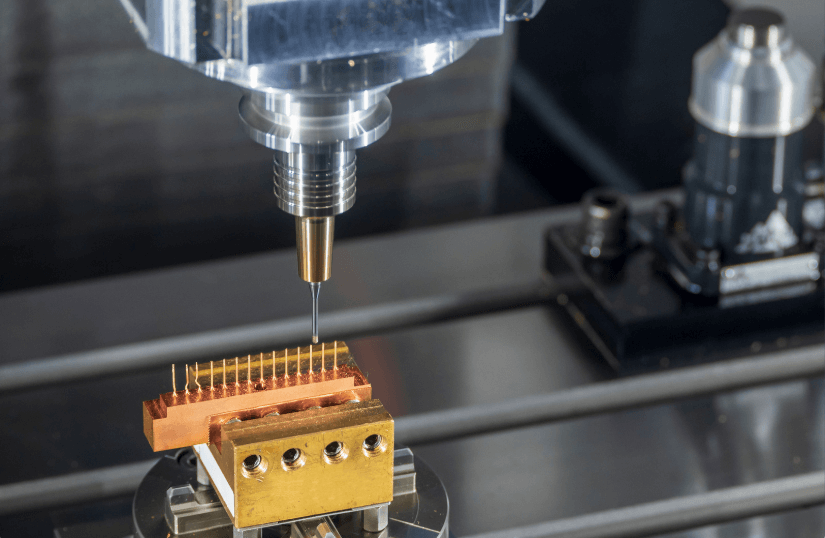

- Robotics: With a minimum human intervention, robots can be programmed to undertake accurate tasks such as assembly and packaging. They are very flexible and are able to operate in various settings, with different materials, different sizes and production demand.

- Artificial Intelligence (AI) and Machine Learning: These are technologies that allow machines to learn using data and get better with time. Even in small batch production, AI could be used to streamline the workflow, predict machine failure, and even aid in product design.

- IoT (Internet of Things): IoT links machines, sensors, and devices throughout the production line and enables them to interact with one another. This forms a smart factory where machines are capable of tuning the production parameters in real time to ensure the optimum level of efficiency.

- Predictive Analytics: Predictive analytics are capable of predicting when a component will break or when production will have to be changed based on the data provided by sensors and machines. This minimizes idle time, and it guarantees constant production in even small batch environments.

Small Batch Manufacturing in the Future

Moving forward, smart automation in small batch production will only increase. In the future, it is probable that we will find even more innovations in automation to enable hyper-customization, real-time production change, and more integrated supply chains as technology keeps evolving.

In the case of small batch manufacturers, being on the forefront is to adopt these innovations today instead of waiting until the competitors jump ahead. Through smart automation, companies will be able to future proof their business, enhance their bottom line and most importantly stay abreast of the constantly changing demands of the market place.

Conclusion

In conclusion, the report has shown that the building of a new bridge is a great idea.

Smart automation is not a buzzword, but it is a revolution in manufacturing, at least when it comes to small batch production. Automation can revolutionize the methods of production and delivery of products by making them more productive, less prone to error, more flexible, and less expensive. It allows companies to achieve the requirements of customization and have high-quality standards and efficient manufacturing processes.

To the directors of supply chains, project managers, and all individuals who deal with industrial automation, adoption of this technology is no longer a choice. It is the formula of remaining competitive in the market that grows to appreciate more and more innovation, precision, and speed. Small batch production is getting smart, and it is time to make the best of it.

When designing injection molds, several critical factors must be taken into account to ensure optimal performance and product quality. Here are the key considerations:

Material Selection: Choose materials that are most suitable to the properties of the intended product (strength, flexibility, temperature resistance) and can be processed in the injection molding process.

Wall Thickness: The part should have uniform wall thickness. An excess of variation in the thickness of the walls can lead to warping, sink marks, or uneven cooling.

Draft Angles: Angles of draft (usually 1-3 degrees) are put on the vertical sides of the design in such a way that the part may be easily taken out of the mold.

Radii and Fillets: The sharp corners should not be used because they may create stress concentration, and the part may be easily broken. Radii or fillets should be used to round corners and edges instead.

Parting Line: The parting line is the line where the two halves of the mold meet. It ought to be positioned strategically and preferably on less visible or functional surfaces.

Ejection Mechanism: The designs should have a proper ejection mechanism which will eject the part out of the mold without damaging the part. This can include ejector pins, sleeves, or air ejection.

Cooling System: Appropriate cooling channels must be established in the mold to make sure that even cooling occurs and avoids the occurrence of defects such as warping or residual stress.

Gate Design: The gate is the place where molten plastic enters the mold. The size, position, and type of the gate (e.g., pin, valve, or hot runner) influence the flow of the part, its appearance, and its mechanical properties.

Tolerance and Fit: Tight tolerances can provide low cost and short lead time. Design components with tolerances that are reasonable and which take into account the drawbacks of the injection molding process.

Draft Angles and Undercuts: Undercuts can be applied, and they can complicate the removal of parts. In case of need, the design must provide such actions as slide mechanisms or collapsible cores to deal with undercuts.