The Dominance of Chinese Injection Molding: A Deep Dive

Go to any store, take any plastic item, and there is a high probability that it was conceived in a Chinese injection molding shop. And that, my friends, is no accident; it is decades of strategic investment, technological development, and simply old-fashioned business acumen that have brought China to the point where it is the undisputed heavyweight champion of the injection molding world.

Outdated Perceptions

However, this is the interesting part: a lot of purchasers continue to refer to Chinese producers with obsolete mindsets. You know, the whole “cheap and dubious quality” image which was never really true. The reality? The injection molding industry in China has become much more advanced than the majority of individuals can imagine.

Why China Dominates

The Numbers Don’t Lie: Cost Benefits That Make Sense

The thing is that the cost advantages of China are no longer all about cheap labor. That may have been the story a couple of decades ago, but the competitive pricing we have today results from something far more strategic.

Consider it like this: when you have a whole ecosystem based on manufacturing, everything becomes more efficient. Raw materials? They are either made locally or imported in huge quantities, bringing down the prices. Specialized equipment? Dozens of suppliers are within a few hours’ drive. Need a particular kind of steel in your molds? No worries—China makes more steel than the last ten countries combined.

I have witnessed injection molding cost savings of 30-40 percent when companies transferred to Chinese suppliers, and that is not only on the per-unit price. It encompasses everything: tooling, setup, even transportation (due to those huge container volumes that make freight rates affordable).

But I want to tell you one thing—it is not a race to the bottom. The efficiency is not the corner-cutting source of savings. Chinese producers have learned to avoid wastage at every stage of the process. They have minimized processes that Western firms are yet to streamline.

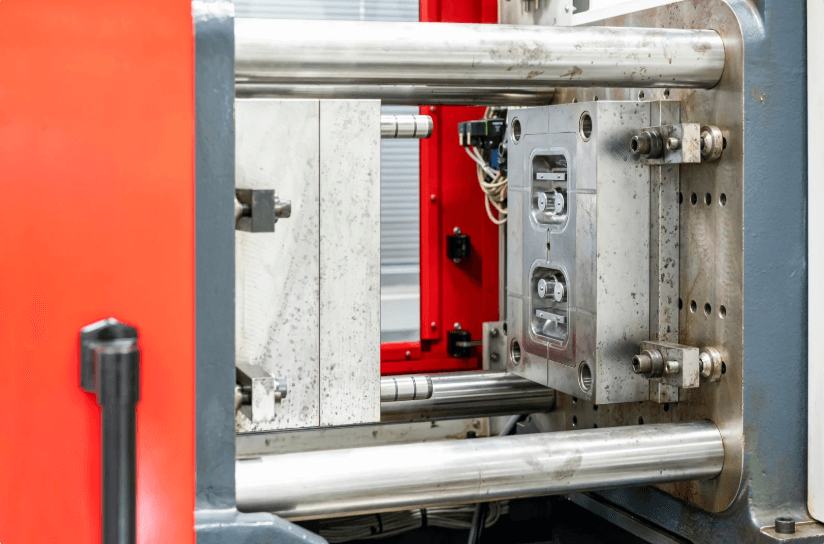

Technology That Will Make Your Head Spin

Do you recall when “Made in China” equated with low-tech, simple manufacturing? Those days are gone. The injection molding plants in China are now operating machines that would make engineers in Silicon Valley drool. We are discussing completely automated production lines with integration of Industry 4.0, quality monitoring systems in real-time, and accuracy that is hard to find in Japan or Germany.

I recently visited a plant in Shenzhen that utilized AI-based quality control mechanisms to identify defects smaller than a human hair. Sensors across the production line could forecast when a machine required maintenance before it broke down. It was a glimpse into the manufacturing future.

Here’s something that particularly struck me: many Chinese producers today invest more in R&D than their Western counterparts. Firms like Foxconn and BYD are not merely imitating Western innovations—they are pioneering them. When Apple needs a new kind of plastic case for the iPhone, where do you think they go?

Scale: Genuinely Difficult to Fathom

Talk about production capacity? The injection molding industry in China is of a size that is hard to comprehend. Imagine 200 or more injection molding machines under one roof within a manufacturing complex in Guangdong province. That is a lot of capacity—more than some entire countries in certain instances. When Samsung had to produce 50 million phone covers in half a year, they didn’t even sweat; it was just another Tuesday for their Chinese collaborators.

The sheer size generates economies that far transcend volume production. With thousands of machines, you build up a level of process optimization expertise that simply cannot be matched by smaller operations. You learn to avoid trouble before it occurs, ensure quality is maintained throughout a huge production run, and master the logistics of transporting millions of parts efficiently.

Remarkably, they can expand or contract with great flexibility. Need a prototype of 100 pieces? No problem. Want to ramp up to 100,000 pieces a month? No problem either. This flexibility is due to the large number of suppliers and subcontractors that can quickly adjust capacity based on demand.

Quality: The Largest Change You Never Heard Of

Let’s address the elephant in the room. Yes, there was a time when Chinese manufacturing was associated with quality problems. But honestly? Times have changed. The last ten years have seen quality advances in Chinese injection molding that are nothing short of stunning. I’m not just talking about ISO 9001 certified facilities with Six Sigma processes and defect rates that many Western manufacturers would envy.

Some of this improvement comes from customer demand. When Tesla, Apple, BMW, etc., begin sourcing through your plants, you can be sure that your quality standards will increase. It’s not a one-time audit and forget it kind of thing; these companies continually monitor, test, and drive improvements.

However, the true disruption has been the incorporation of superior quality control systems. Chinese manufacturers have invested heavily in automated inspection devices, statistical process control, and real-time monitoring systems. Many plants can intercept and rectify quality problems before the customer is even aware of them.

Conclusion: The Future of Injection Molding in China

The dominance of China in injection molding is not only a present reality but is expected to increase over time. The competitive moat formed by investments in technology, economies of scale, supply chain integration, and constant quality improvements makes it hard for other regions to bridge that gap.

This presents both an opportunity and a necessity for buyers. The potential is clear: access to high-quality manufacturing facilities at reasonable costs. The imperative is equally obvious: in most markets, you simply cannot be competitive unless you leverage these benefits.

The companies that recognize this soon—establishing good rapport with Chinese injection molding partners and effectively incorporating them into their supply chains—will enjoy significant advantages over those that resist or take too long to adapt.

In a global marketplace, it’s not a matter of whether you need to consider Chinese injection molding suppliers. The real question is: can you afford not to?