Undercuts

An undercut is a part of the mould where the molten plastic flows behind a retaining section thereby preventing the hardened plastic moulding from being easily ejected. Undercuts, in general, require moulds with moving parts to allow the product to be demoulded although parts may be stripped from the core provided that certain conditions are met.

For rigid plastics, the part may be stripped if the undercut angle is not more than about 2°. Larger angles will induce stresses into the part on stripping even if the part is deformable enough to allow stripping at all. If the material is a softer plastic (e.g. plasticised PVC),then larger angle undercuts can be acceptable, but even so, large undercuts will need hand stripping.

Larger angles will induce stresses into the part on stripping even if the part is deformable enough to allow stripping at all. If the material is a softer plastic (e.g. plasticised PVC),then larger angle undercuts can be acceptable, but even so, large undercuts will need hand stripping.

A screw thread is a common form of the undercut. Products with screw threads usually require a mould with an unscrewing core in order that the product can be demoulded without unscrewing the product from the mould by hand. Exceptionally,where the screw thread is of shallow depth and the material is sufficiently flexible,the part may be stripped from the core.

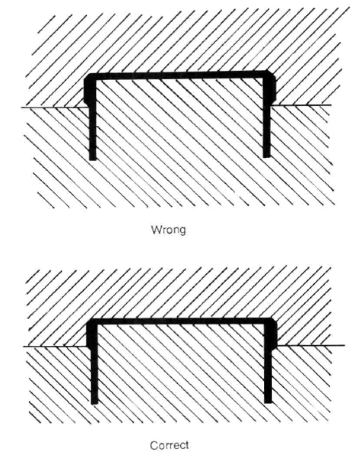

The problem of undercuts can often be solved by selecting the correct mould parting (split) line so that it avoids an undercut altogether. Figure 1 shows the essential features of a cylindrical cap for a jar being moulded with the parting line wrongly placed, producing an undercut, and correctly placed to avoid the undercut.

Surface finish

The finish required on the product determines the finish required on the mould surface. A high gloss finish to the product requires a mould of high quality nichrome steel or a tool steel with a highly polished chromed surface.

Such moulds are expensive to produce because of the lengthy polishing treatments and the need still to maintain dimensional specifications. In some cases, textured surfaces are a design feature,either to achieve a particular effect or to mask problems resulting from moulding.

Such problems arise,for example, when mouldings are made from expanded plastics or glass-filled plastics. Texturing a mould surface also increases the cost of the mould but the increase in cost can be minimised by using simple texturing.