Table of Contents

Common Steel Grades Used for Injection Molds

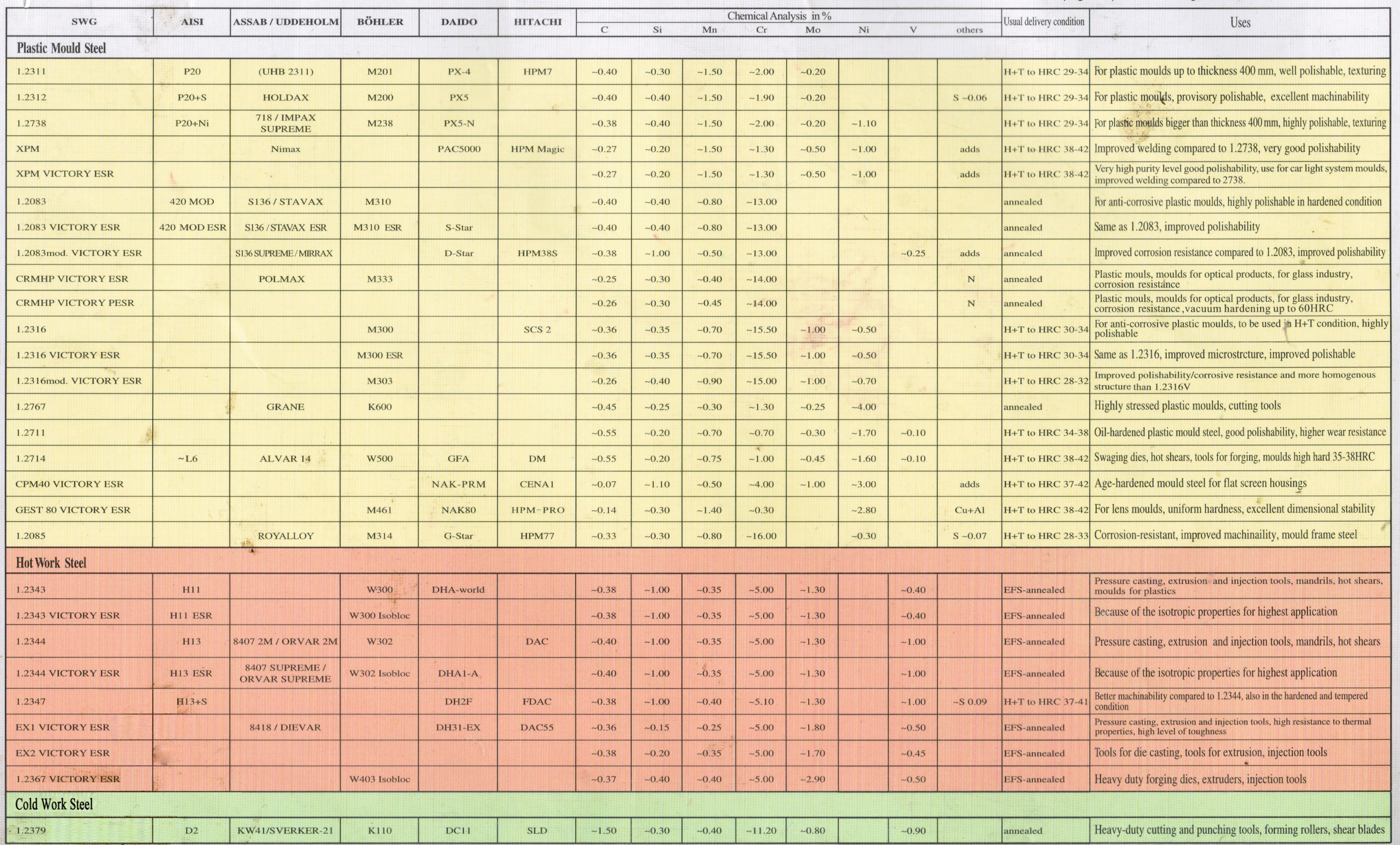

There are several steel grades commonly used for injection molds including:

P20 Mold Steel

P20 is a versatile, pre-hardened mold steel that can be heat treated to higher hardness levels. It has good machinability and polishability. P20 is often used for low to moderate production molds for parts made of thermoplastics.

H13 Mold Steel

H13 is a versatile chromium hot work steel that is pre-hardened. It has excellent thermal fatigue resistance and can withstand the stresses of repeated heating and cooling cycles. H13 is commonly used for molds with moderate to long production runs, especially for parts made of engineered plastics.

S7 Mold Steel

S7 is an air hardening, high-carbon, high-chromium steel. It offers a good balance of wear resistance, toughness, and stable dimensions during heat treatment. S7 is used for larger molds and long production runs of over 500,000 cycles.

420 Stainless Steel

420 stainless steel offers good corrosion resistance for molds exposed to moisture. It is often used for food and medical industry molds where corrosion resistance is critical. 420 stainless has lower hardness than tool steels, limiting its use in high wear areas.

1018 Mild Steel

1018 mild steel is very machinable and affordable. It is often used for prototype molds before higher grade production molds are built. 1018 mold steel has low hardness and is only suited for very low volume production.

Factors to Consider When Choosing a Steel Grade

Several factors should be considered when selecting an injection mold steel grade including:

Part Requirements

Consider the material being molded and any special features needed in the final part like threads, inserts, texturing, etc. More complex parts often require higher grade mold steels.

Production Volume

Lower steel grades like P20 and 420 stainless can be used for production runs under 100,000 cycles. For higher volume production, H13, S7, or other tool steels are recommended.

Cost

Mild and stainless steels offer cost savings for very low production molds. Pre-hardened P20 and 420 stainless provide moderate cost savings. H13 and S7 are premium grades but best for high volume molds.

Comparing the Advantages and Disadvantages of Each Steel Grade

Here is a comparison of the key advantages and disadvantages of common injection mold steel grades:

Machinability

- P20 has excellent machinability in the pre-hardened state.

- H13 machines well but not quite as easily as P20.

- 420 stainless has good machinability for a stainless steel.

- S7 is more difficult to machine than other common mold steels.

Hardness

- 1018 mild steel has very low hardness after machining.

- P20 can be heat treated to the mid 40s Rockwell C.

- 420 stainless achieves around 25-30 Rockwell C.

- H13 reaches 50-52 Rc after heat treatment.

- S7 has hardness levels up to 56 Rc.

Corrosion Resistance

- 1018 and P20 have low corrosion resistance.

- 420 stainless steel offers the best corrosion resistance.

- H13 and S7 have moderate corrosion resistance.

Cost

- 1018 is the most economical option.

- P20 provides a good value for many applications.

- 420 stainless is moderately priced.

- H13 and S7 are more expensive premium grades.

Best Uses for Each Steel Grade

Based on properties, these are typical best uses for each grade:

| Steel | Hardness | Cycles | Uses |

|---|---|---|---|

| P20 | 28-32 HRC | Up to 100k | Wide range of thermoplastics, cost-effective for low to moderate production |

| H13 | 48-54 HRC | Up to 250k+ | Engineering plastics, moderate to high production molds |

| S7 | 50-58 HRC | 500k+ | Complex, high production molds needing wear resistance |

| 420 Stainless | 48-50 HRC after harden | Varies | Corrosion resistance for food, medical applications |

| 1018 Mild | 120 HB max | <1k | Prototype molds, not for production |

Conclusion

Choosing the best steel grade for an injection mold requires balancing factors like part requirements, production volume, cost, machinability, and properties like hardness, corrosion resistance, and thermal fatigue strength. Mild steel works for prototypes. P20 offers versatile performance for low to moderate production. H13 is widely used for high volume molds. S7 and other premium alloys are best for the most demanding production runs. Consider both the advantages and disadvantages of each grade for your specific application.

FAQs

What steel is best for making injection molds?

For most production molds, P20 or H13 offer the best combination of machinability, properties, performance, and cost-effectiveness. P20 works well for lower volumes up to 100,000 cycles. H13 is excellent for higher volume molds above 100,000 cycles.

What steel is easiest to machine for injection molds?

1018 mild steel machines the quickest and easiest due to its low hardness. P20 steel also has very good machinability in its pre-hardened state. Avoid S7 if machining time and cost are critical.

Which steel grade offers the best hardness for injection molds?

S7 tool steel achieves the highest hardness and wear resistance after heat treatment, ranging from 52-56 Rc. H13 tool steel also provides good hardness around 50-52 Rc. For maximum mold tool life, S7 and H13 are best.

When should 420 stainless steel be used for injection molds?

420 stainless should be used when the mold or molded parts will be exposed to corrosion from moisture or chemicals. This is common in food processing and medical applications. The lower hardness limits 420 for high wear areas.

What steel is used for prototype injection molds?

For low volume prototypes, 1018 mild steel is commonly used. It machines extremely fast and cheaply but lacks hardness for more than a few test cycles. Once validated, prototypes should be remade from P20, H13 or other harder mold steel grades.

Here is a comparison chart of equivalent injection mold steel grades from different countries, including their applications, typical characters, hardness, and treatment:

| China | USA | Japan | Germany | Sweden | Application | Typical Characters | Hardness | Treatment |

|---|---|---|---|---|---|---|---|---|

| P20 | 718 | S136 | 1.2311 | 2311 | Low-run production molds, prototypes and other molding applications | Good surface finish, high toughness | 28-32 HRC | Prehardened, can be polished |

| 718 | NA | S136H | 1.2738 | 2312 | Production molds with high production rates | High-precision, high toughness, good polishability | 33-37 HRC | Prehardened, can be polished |

| NAK80 | NA | SKD61 | 1.2344 | 8407 | High-quality molds with high precision and long life | High strength, high toughness, good heat resistance | 37-43 HRC | Prehardened, can be polished |

| S136H | NA | SKD11 | 1.2083 | 420 | Molds for high-volume production | High precision, good surface finish, high wear resistance | 38-45 HRC | Prehardened, can be polished |

| H13 | NA | NA | 1.2343 | 8402 | High-volume production molds | High toughness, good wear resistance | 44-52 HRC | Heat treated for increased hardness and toughness |

| 420 | 420 | SUS420J2 | 1.2083 | 4Cr13 | Molds for general use | High hardness, good corrosion resistance | 48-52 HRC | Heat treated for increased hardness and toughness |

| 1045 | 1045 | S45C | C45 | 1.1191 | Low-volume production molds and inserts | High toughness, good machinability | 20-25 HRC | Heat treated for increased hardness and toughness |

Note: NA stands for “not applicable” or “not available.”