This scope is suitable for injection working unit of injection workshop .

Plastic mold operation key points:mold transport,mold assembly ,connection of mold cooling water hose ,confirmation for oil hose and limit switch connection,molding job, processing the flash for overfilling ,usage of regrinded materials ,inspection points for finished mold.the maitenance of mold .

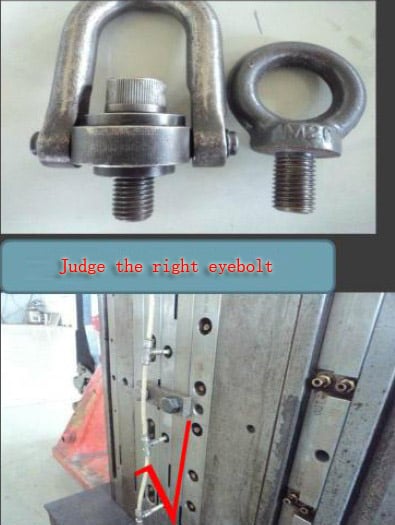

Eyebolt selection

1,Confirm the specifications of the eyebolt. Check the eyebolt hole :metric or the British ,Choose matching eyebolt before installation.

2, Check eyebolt for its breakage, cracking, deformation .

3,Confirm the wire rope to be free of rust,no obvious deformation,no broken wire.Check the lock plate for A and B plates. The lock plate should be used under the mold transport.

Reverse the mold

1,The rubber or wood should be used for cushin to prevent the collision and damage of the mold.

2,Check the circumstance before the reversaling to check the possible collision of mold components like:water plugs, springs, bolts, and etc. if any risks,they should be dismantled before handling.After that,those componenst should be reassembled to the mold again.

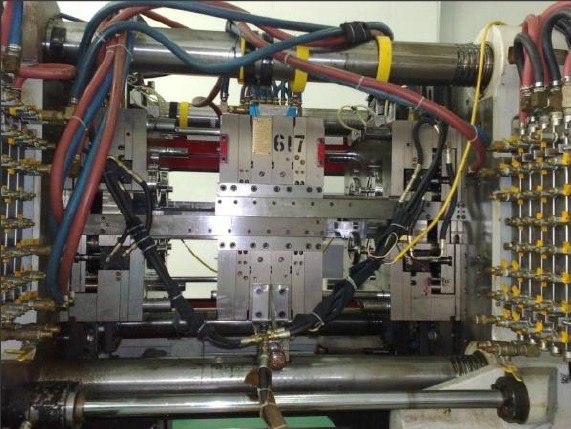

Fasten mold to injection machine

1,After estimation of the mold weight and molding situation,the right clamping bolt could be adopted. Mold weight over 1 Ton,the clamping bolt should not be less than 8 pieces on the A and B plates,mold weight below 1 Ton,4 clamping bolts should be used on the both plates.

2, ejection bars should be same length and diamter for the balance pushing to the ejector pins plate.when the ejection bars retrack,there sould have a gap between the bars and jector pins plate.

If ejector pins plate is forced to recover place ,the connecting screws should be adopted,and no gap need.

Connection of water hose

1, After connection of the cooling hose and water plug,confirm the connection situation by hands

2, Water plug of “water out” and “water in” should be connected correctly according to the specified sequence ,any changed sequence would have a negtive impact on the quality of finished part.

3,To avoid possible interfering with the cooling water hoses when mold is opening and closing,it should use the appropriate length of the hose.

4,If the longer hoses is unavoidable, the proper length should be arranged properly to prevent to bruise water hose and damage mold.

Click for Operation of Plastic Mold-2