Automotive Bumper Mould Maker in China

DFM-first engineering • Hot runner / sequential valve gate options • Stable mass production support

Automotive Bumper Injection Moulds: Tooling + Production Support

DFM-first engineering • Hot runner / sequential valve gate options • Stable mass production support

- Mould TypeFront bumper / rear bumper / bumper cover moulds

- Part SizeTypically 1500–2500 mm (project-dependent)

- MachineTypically 2500–3500 tons (depends on size/material)

- RunnerCold runner or hot runner; sequential valve gate optional

Quick Facts: Automotive Bumper Mould

- Mould type: front bumper / rear bumper / bumper cover moulds (passenger car, SUV, commercial vehicles)

- Typical bumper length: about 1500–2500 mm (project-dependent)

- Typical clamp tonnage: about 2500–3500 tons (depends on part size/material)

- Runner system: cold runner or hot runner; sequential valve gate optional for cosmetic control

- Steel options: P20 / 2738 / 718H / H13 (based on resin, output, and surface requirement)

- Typical cycle time: around 90–150 s (depends on thickness and cooling)

If you want a fast and accurate quotation, send your 3D file (STEP/IGES) and requirements. We reply with a tooling strategy (gate/cooling/ejection) and a clear lead time plan.

Qu'est-ce qu'un moule pour pare-chocs ?

A moule de pare-chocs is a specialized tool used to produce automotive bumpers by injection moulding. It is designed for large part size, stable dimensional control, and consistent surface quality. A well-built bumper mould helps manufacturers improve repeatability, reduce rework, and maintain reliable assembly fit.

Understanding Bumper Moulds: Key Points That Affect Quality

- Gate & runner strategy: controls weld lines and surface appearance on A-surface areas

- Cooling balance: the main factor for warpage control on large bumper parts

- Venting: prevents trapped gas, burn marks, and short shots

- Ejection design: avoids visible ejector marks on cosmetic areas

- Steel & heat treatment: supports tool life and stable production

Related reading: fundamental principle of injection moulding.

How to Choose the Best Bumper Mould: Practical Checklist

- Steel & wear resistance: choose suitable steel grade for resin type and expected output

- Size & parting strategy: confirm parting line, undercuts, sliders/lifters, and part size match

- Cooling design: optimized water channels/conformal ideas to reduce warpage and stabilize cycle time

- Hot runner / sequential valve gate (optional): helps improve cosmetic quality and weld line control

- Supplier capability: verify automotive tooling experience, sampling deliverables, and after-service

Topworks Automotive Bumper Mould Capabilities

Topworks focuses on automotive bumper mould making with DFM-first engineering and production-oriented tooling design. With 10+ years of experience in tooling and manufacturing, we support both prototype/bridge tooling and production moulds in-house.

We manufacture custom bumper moulds, including hot runner (sequence timer control / valve gate options) and runnerless solutions based on your part design and appearance requirements. We also support assembly/machining needs when the project requires tight fit or special features.

We use steel options such as P20 and 2738 for automotive bumper moulds, and we design gating, cooling, and venting to achieve stable parts with consistent quality.

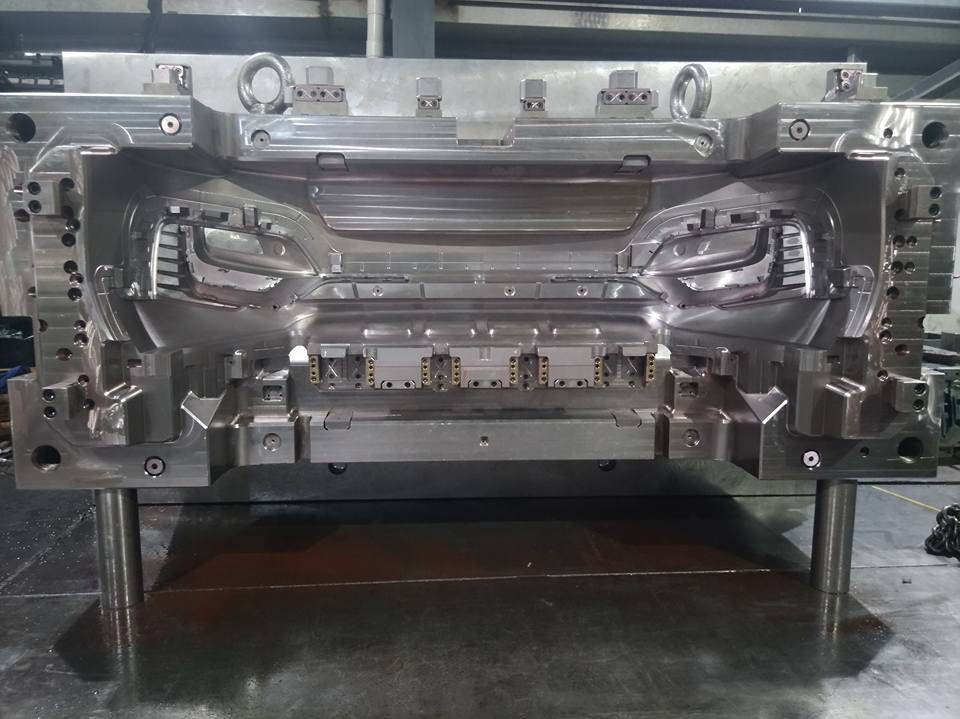

Automotive Bumper Mould Photos

"Je suis heureux de vous informer que toutes les pièces en plastique sont parfaites ! Nous sommes ravis, et il y a donc de bonnes chances de poursuivre notre relation pour tout nouveau projet à venir."

CRISTIANO

Italie

"Steven est un chef de projet et un ingénieur très soucieux du détail, capable de résoudre les problèmes de manière créative et de fournir un excellent service. Ce fut un plaisir de travailler avec lui."

DAVID

U.S.A.

Le besoin de fabricants de moules pour pare-chocs spécialisés

Bumper moulds have unique requirements compared to regular plastic injection moulding. The moulds must withstand high impact forces yet produce precise, durable plastic car bumpers. Automotive moulds use acier de qualité supérieure and machining than consumer product moulds. The mould maker must have expertise in high-tolerance mould design to account for complex curved surfaces, large part size, and appearance control.

If you choose a mould maker without automotive experience, you may face unstable lead times, inconsistent wall thickness, surface defects, and assembly fit issues. A qualified supplier should demonstrate clear design control, machining capability, and a repeatable sampling process.

RFQ Checklist (What to Send for a Fast Quote)

- 3D file: STEP / IGES

- 2D drawing: key dimensions, tolerances, datum references

- Material & color: PP / modified PP / talc or GF reinforced / PC/ABS / TPO, etc.

- Cosmetic definition: A/B/C surfaces + acceptable weld line/gate vestige zones

- Annual volume & target output: expected production plan and cycle time target

- Assembly requirements: vehicle model fitment notes, critical interfaces, clips/holes

Process: From DFM to Production

- DFM review: parting line, draft, undercuts, gating, cooling, venting plan

- Mould design: runner balance, cooling layout, ejection strategy, slider/lifter design

- Machining & assembly: CNC / EDM / heat treatment / polishing / fitting

- Sampling (T0/T1): trial shots + dimensional check + improvement list

- Approval: golden sample + documentation for repeatability

- Mass production support: process window + maintenance plan

Car Bumper Mould FAQ

Q1 : Quels sont les moules pour pare-chocs de voiture que vous produisez en Chine ?

We manufacture injection moulds for pare-chocs avant, pare-chocs arrière et protections de pare-chocs in passenger cars, SUV, and commercial vehicles. We support different bumper sizes and can design custom moulds with internal or external parting strategies to match appearance requirements.

Q2 : Quelle est la durée de vie d'un moule d'injection pour pare-chocs de voiture ?

Tool life depends on part design, resin, steel grade (commonly 2738, 718H, or H13), maintenance frequency, and production conditions. With proper cleaning and cooling channel maintenance, bumper moulds can keep stable performance over long runs.

Q3: What is the average production cycle of car bumper moulding?

Typical cycle time ranges around 90–150 seconds depending on bumper size, wall thickness, and cooling needs. We optimize cooling and runner design to improve stability and efficiency.

Q4: Do your car bumper moulds adopt hot runner systems and sequential valve gating?

Yes. We can supply bumper moulds with hot runner solutions and multi-point sequential valve gate systems to help control weld marks on visible surfaces, which is important for automotive exterior parts.

Q5 : Quel est le délai de fabrication d'un moule de pare-chocs de voiture personnalisé en Chine ?

The typical mould delivery time is often 70–80 days after final design approval, depending on complexity and specifications. It includes machining, EDM, heat treatment, polishing, assembly, and mould testing.

Q6: What plastic material is used for car bumpers?

Common materials include PP, modified PP, talc or glass fiber reinforced PP, PC/ABS blends, and TPO. We can suggest options based on impact requirement, temperature resistance, and regulatory needs.

Q7: Do you make multi-cavity car bumper moulds?

Most bumper moulds are single-cavity because of large part size and high clamp tonnage. We can support family mould concepts for certain left/right parts or 1+1 setups when feasible.

Q8: Are you able to make customized car bumper moulds?

Yes. We support complex bumper mould designs including hidden parting strategies, lifters for undercut features, sliders for side mounting holes, and optimized gating/cooling/ejection to reduce defects and improve appearance.

Get a Fast Quote for Your Bumper Mould

Send your 3D file + material + surface requirement. We’ll reply with DFM notes, tooling strategy, lead time, and a clear quotation.

Fast RFQ tip: STEP/IGES + material + A/B/C surface definition helps us reply faster with the right gate/cooling strategy.