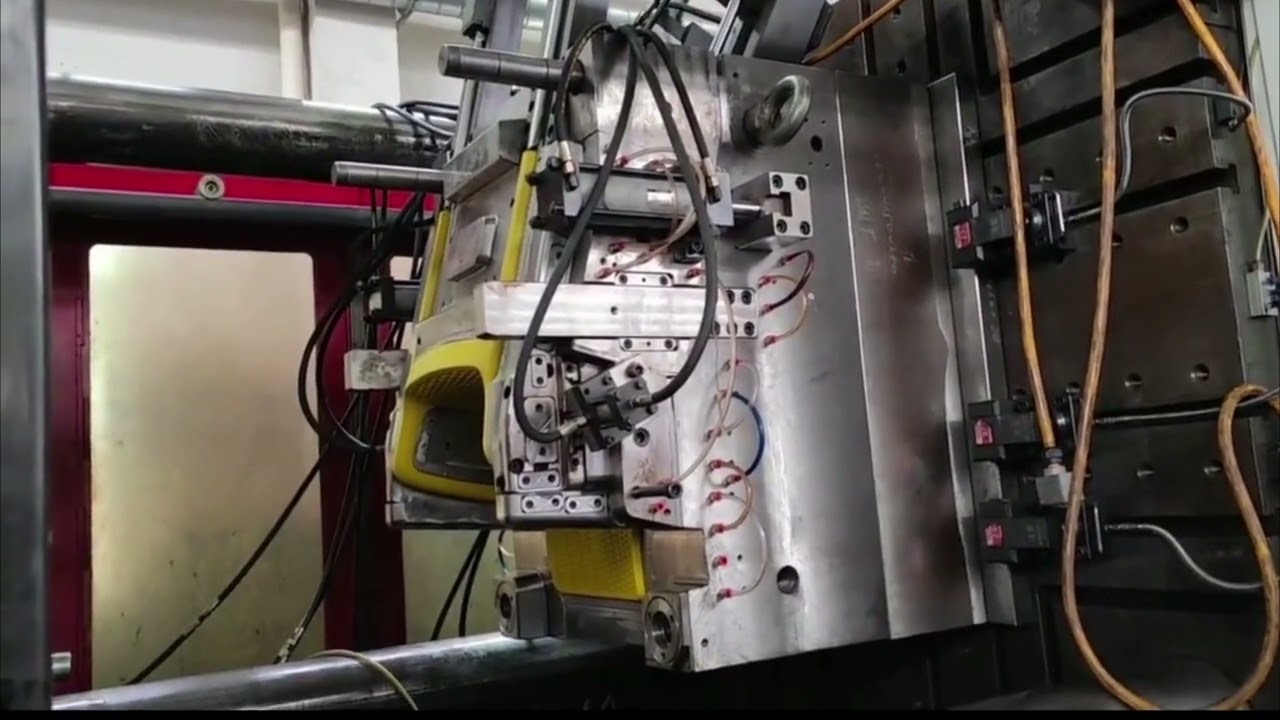

What is Chair Mould?

A chair mould functions as an advanced manufacturing tool that produces top-tier chair components. The production efficiency depends on chair moulds, which provide both precision and durability.

- Assess Suppliers:

Research chair mould suppliers that have earned a good reputation. Who you choose as your manufacturer will directly affect how well your mould functions.

- Evaluate Design:

Check the different design requirements available for chair moulds. Better production efficiency is achieved with well-made moulds.

- Ask for Samples:

Get samples of chair moulds from a number of different manufacturers. You should check the quality and functions of a chair mould by requesting samples from several manufacturers.

- Place an Order:

Order the chair mould after you’re happy with the samples and the product follows your requirements.

Usage Scenarios

- Efficient production of many chair parts is possible with the use of mass production.

- Custom Furniture: A perfect way to make chairs that fit a client’s unique needs.

- Making a prototype: A great solution for checking a chair’s design before it is built on a larger scale.

Chair Mould, Plastic molded chair

We present our advanced Chair Mould which fulfills all industry requirements at their peak. Our seasoned experience in mould manufacturing allows us to deliver a product which delivers outstanding quality together with peak performance.

High-Volume Production Capabilities

We are able to create many chair moulds using advanced processes without lowering our quality level. You will get your chair moulds without delay through this effective system which makes it the best solution for manufacturers needing higher production speeds.

Fast and Reliable Project Delivery

The design of our chair moulds emphasizes durability together with exact precision. These chair moulds are constructed using durable materials together with modern engineering techniques which make them highly resistant to continuous usage and provide excellent chair production results according to your product requirements. Each and every production cycle delivers premium results due to our moulds which serve residential and commercial applications.

The technical support team provides continuous assistance to all our product users. The team of experts stands by to provide support and answer any questions you might have so your production process integrates without issues our chair moulds.

Our chair mould represents reliable manufacturing technology which combines experience, operational excellence and productivity. We are ready to discuss business support options with you as part of our current contact initiatives.

Topworks has got the skills to whip up fully-built chair molds using top-notch plastic and steel, all while keeping it speedy and precise. Plus, you can totally customize the molds to fit your exact needs.

And here’s the best part: we can handle all your fabrication right from our place. Whether you need a few small molds for chairs or a whole bunch of them for big production, we’ve got you covered. Our range of services is designed to meet every client’s needs, saving you both time and money.

Chair mould arrangement

- chair mould:

- mold cavity: 1

- runner: hot runner

- mold cavity steel: P20

- mold core steel: P20

- mold slider insert: DIN 1.2738 with Nitriding

- The core insert activation:2 Hydraulic Cylinders

- Plastic material: HDPE

Topworks chair mold pros:

- We’re pros at making all sorts of moulds like those for toilets and chair seats and even outdoor chairs.

- Our plastic moulds for chairs are top-notch and priced just right.

- We offer regular support for any technical stuff or service issues you bump into.

- Our team has plenty of experience and skills to get the job done.

- The chair moulds we design are crafted by qualified designers who know what they’re doing.

- You can count on our moulds to be durable and last a long time.

- We pride ourselves on delivering perfect and high-quality work.

- You can trust us for on-time delivery of your chair moulds.

FAQ:

What kinds of chair mould and stool mould do you offer?We focus on molds for plastic chairs and stools, which include dining chairs, outdoor leisure chairs, armchairs, baby and child chairs, bar stools, step stools, folding stools, and chairs. Based on your designs or samples, we offer custom drafting as well.

What materials are used for your molds? Typical chair and stool mold steels used are P20, 718, S136, and NAK80, and are selected based on the product needs and your budget.

Platen: standard, or custom Stoppers: high-precision guide pins, bushings, lifters, sliders, and ejector systems from SMC and other brands. Cooling and hot runner systems are available on request.

What plastic resins are appropriate for chair and stool molding? PP, HDPE, PC, PA+GF (for high strength), and when possible, recycled. Based on the required strength, surface finish, and price, we choose the most suitable resin.

Can you develop molds from my drawing or sample? Yes. We develop molds from 2D/3D (STEP, IGES, DWG) files, as well as physical samples. Our engineering team conducts DFM and proposes options for wall thickness, draft angles, ribs, and gates, and then we provide you with a feasibility report and quote.

Do you provide DFM and design optimization? Definitely.We assist with DFM (Design for Manufacturability), mold flow analysis (fill, pack, cool, warp), and cycle time, strength, and stable production structural optimizations.

What is the typical mold lead time? 30-60 days for standard chair and stool molds, starting from design approval. Lead times may vary due to the selection of steel, surface finish, and availability of hot runners.

What is your pricing model? Pricing is based on product size and complexity, steel grade, the number of cavities, surface texture, and components (hot runner, hydraulic core pulls, etc.) included. We provide detailed quotations and specify the scope of work, delivery and payment terms, and warranty.

What information do you need to quote? 2D/3D product drawings or chair or stool dimensioned photos (samples) Target material (resin), weight and wall thickness Expected annual volume and cycle time Press tonnage and machine specs (injection, clamp force, shot size) Required surface (polish, texture, color) and functional tests

Do you provide samples and trial runs? Yes. We provide sample parts, trial reports, and suggestions for improvements. Remote/ on-site trials, videos, and parameter sheets are available. T0/T1/T2 mold trials are performed.

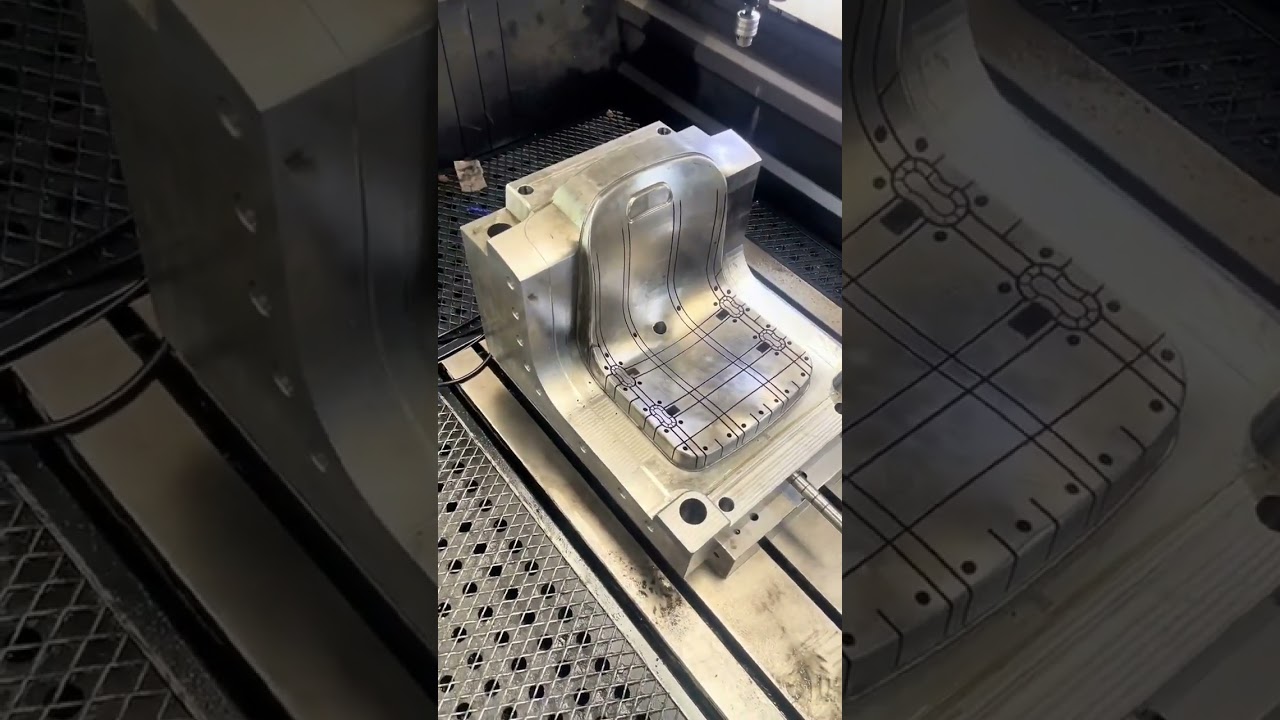

Chair and Toilet Seat Mold Manufacturing Process

The production of molds for chairs molds for toilet seats generally includes the following actions:

- Design and Engineering

- Make 3D sketches and CAD models according to the requirements of chairs.

- Use mold flow analyses to copy the process of making chairs

- Core, cavity, slides and ejectors are part of a design chair mold.

- Tooling and Machining

- Raw blocks are molded into parts using EDM, CNC and similar production processes…

- The surface of the mold tool has been made free of roughness.

- Put all the parts, cavity, core and others, into the chair mold.

- Testing and Validation

- Perform dry test runs to verify molds and machine motions

- Run tests on actual production runs, and adjust parameters of the production process

- Verify that the performance of chair molds is in line with standards

- Maintenance and Monitoring

- Be sure to check and clean molds on a regular basis.

- Check the quality of the performance all the time.

- Change components when necessary following the maintenance schedule.

The article below describes each of the key stages. Further explanation can be offered on the specific methods, equipment and reviews and validations at every step of making high-quality chair and toilet molds.