Local thick wall thickness, wrong position of gates and cooling layout would lead to sink marks, trapped air, deformation and burns on the injection parts, the following will analyze some factors:

Wall Thickness:

The wall thickness should keep same to avoid the sharp transition zone and big different cross-section.Otherwise, they will invite the uneven shrinkage, which is a reason for the drawback of the surface.The wall thickness scope is between from 1 to 6mm; normal average thickness is 1.8~3mm,which depends on the geometry of plastic part and plastic material.

Also the wall thickness design is related with the flow distance of the melt plastic; the flow distance is a cover space of melt plastic from gate to the far end of the cavity. Under normal process, the flow distance is proportional to the thickness of plastic parts. The larger the plastic wall thickness is, the longer the flow distance will be.

The flow distance lists as follows for wall thickness 2.5mm

ABS : 220 mm; PC : 120 mm;

HDPE:280 mm; POM : 180 mm;

the problems invited by uneven wall thickness:

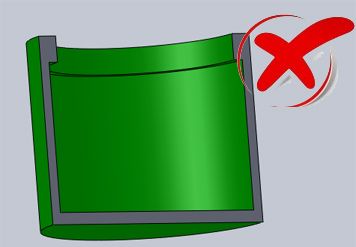

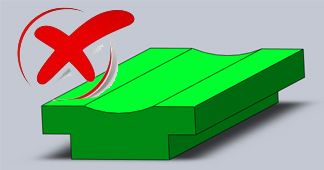

1.Local thick wall would lead to the sink marks on the surface:

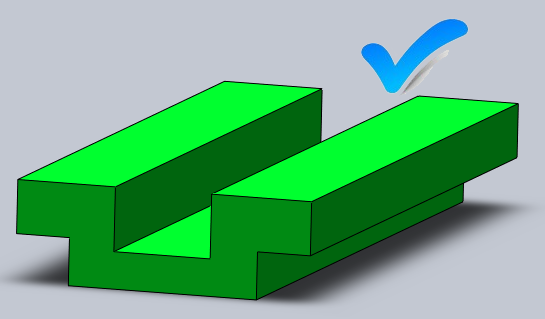

The thin wall would lead to hesitation flow

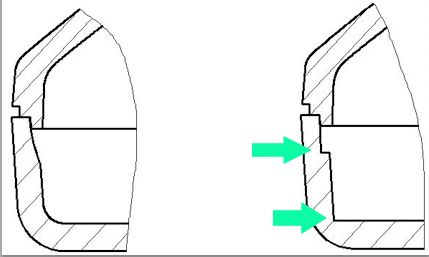

Spigot: gradual transition wall thickness design would eliminate the white spot on the surface

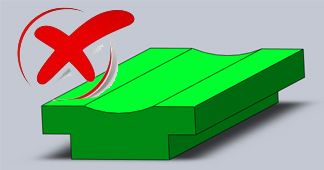

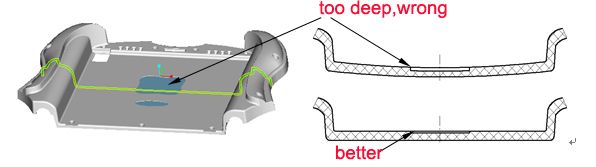

On the picture below, the slot is too deep, which lead to the deformation of the bottom and the solution is to deduce the depth of the slot and make the wall thickness even.

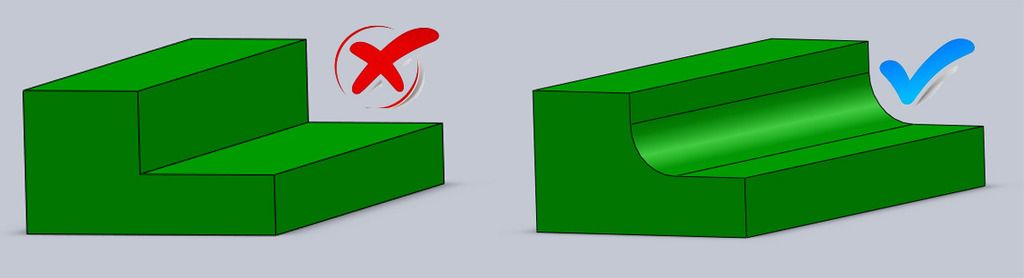

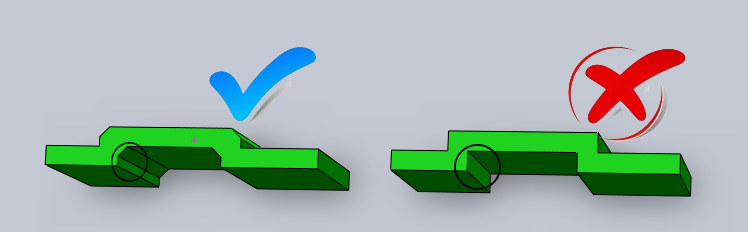

Glossing: the sharp corner will lead to glossing

Component wall thickness requires several competing factors to be taken into consideration. The mechanical requirements of a section may dictate a certain wall thickness. However, thick sections should be avoided because of the requirement to remove heat efficiently (the cooling part of the cycle is the time that limits the production rate), the need to avoid sinking,cavitation and warping. Thin sections should be avoided because of the need for the melt to flow easily to fill the cavity. Economic factors often dictate the final wall thickness selected (amount of material used, etc.). If a wall is too thin for the strength properties required, the wall can he reinforced with ribs (see below). Flow characteristics vary from one plastics material to another and Tabic 1.2 gives typical values for wall thicknesses.

Wall thickness recommendations (mm)

| Material | |

| ABS | l.00-3.50 |

| Acetal | 0.50-3.15 |

| Acrylic | 0.65-3.80 |

| Cellulosics | 0.65-10.00 |

| Liquid crystal polymers | 0.20-3.00 |

| Long fibre plastics (Vcrtons) | 1.90—25.00 |

| Nylons | 0.25-2.95 |

| Polyarylate | 1.15-3.80 |

| Polycarbonates | 1.00—3.80 |

| Polybutylene terephtha丨ate | 0.65-3.20 |

| Polyethylene (LD) | 0.50-6.35 |

| Polyethylene (HD) | 0.75-5.00 |

| Polyphenylene sulphide | 0.50-4.55 |

| Polypropylene | 0.65-3.80 |

| Polysulphoncs | l.(X)-3.80 |

| Modified PPO | 0.75-3.55 |

| Polystyrene | 0.85-3.80 |

| SAN | 0.85-3.80 |

| UP VC | 1.00-3.80 |

Range of flow path ratios for some common plastics

| ABS | 80-150 |

| Acetals | 100-250 |

| Acrylic | 100-150 |

| Nylon 6 | 140-340 |

| Nylon 6,6 | 180-350 |

| Polybutylenc tcrephthalatc | 160-200 |

| Polycarbonate | 30-70 |

| Polyethylene (HD) | 150-200 |

| Polypropylene | 150-350 |

| Polystyrene | about 150 |

| HIPS | about 130 |

| Polysulphoncs | 30-150 |

| Polyvinylchloride (unplasticiscd) | about 60 |

| Polyvinylchloride (plasticised) | up to 180 |

| SAN | about 140 |

Table 1.3 Courtesy of J.A. Brydson (1990) Handbook for Plastics Processors% Hcincmann Newncs.

Wall thickness should be constant if possible. If not, the transition between thick and thin sections should be gradual because abrupt changes lead to internal stresses due to flow problems and different cooling rates. In general,the ratio of thick to thin should not be greater than 3:1. A further point is that in filling such a section, the flow must be from thick to thin.

For any section thickness,there will be a limit to the length of flow (flow path) possible. This is because as the plastic melt flows along a section,it cools producing an increase in melt viscosity and ultimately it sets up (hardens) thereby preventing the section from being completely filled. The ability to flow along a path depends on the path thickness, the type of plastics material and the particular grade (easy flow or stiff flow) of that material. It will also depend on moulding conditions. A guide to flow characteristics of materials in this respect is given by the flow path ratio which is the ratio of the length of flow possible per unit wall thickness. Table 1.3 gives the range of flow path ratios for some common plastics materials.